Occupational Health and Safety

Our Approach

SUBARU regards occupational health and safety as a critical management issue. Our fundamental philosophy in this area is “SUBARU makes health and safety the first priority in all our work,” and we have formulated the Basic Health and Safety Policy based on this. Furthermore, each of SUBARU’s affiliated companies in Japan and overseas establishes their own occupational health and safety policies in line with their business details, regional characteristics, and local laws and regulations, and implements initiatives based on these policies.

Basic Health and Safety Policy

With the aim of reducing industrial accidents, traffic accidents, diseases, fires, and other disasters to zero, every individual will strive to create a safe, comfortable workplace through efforts to improve facilities, environments, and work methods, and to enhance management and awareness, based on a shared recognition of the importance of health and safety.

Established in April 2002

Management System

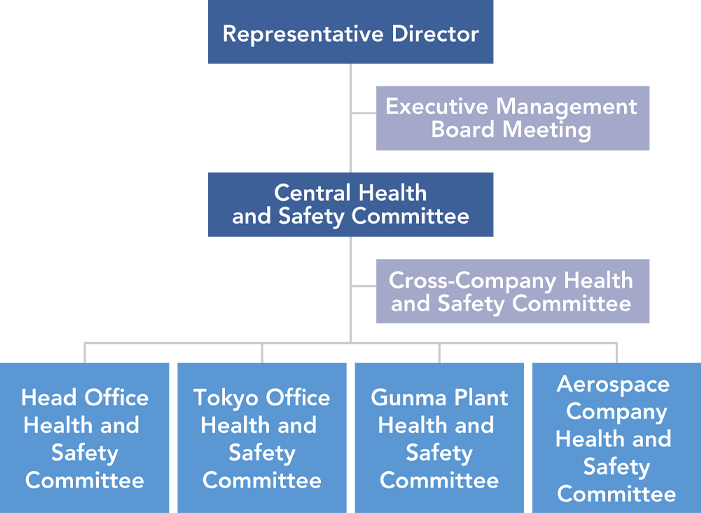

Health and Safety Organization Chart

Central Health and Safety Committee

SUBARU and its affiliated companies have established the Central Health and Safety Committee with the aim of preventing industrial accidents and illness, and improving the working environment for all employees (including temporary employees). The committee fosters occupational health and safety activities as well as initiatives for health management. The committee is chaired by the executive officer in charge of the Human Resources Department (as of March 31, 2025), and the vice-chairperson is elected from the labor union. In addition, managers in charge of health and safety at each site are also members of the committee. The committee meets for deliberations three times a year, primarily deliberating on occupational safety, occupational health, traffic safety, and fire and disaster prevention.

Topics in FYE March 2025

- Occupational safety: Sharing examples of industrial accident prevention measures at each site and their effects

- Occupational health: Sharing of activities in technological development departments, which saw significant improvements in mental health in FYE March 2024

- Other: Issues and actions regarding the complete smoking ban on our premises starting in April 2025

Site Health and Safety Committee

Each site has established a health and safety committee linked to the Central Health and Safety Committee. At meetings of each of these health and safety committees, SUBARU employees, affiliated companies and resident contractors on our premises under their purview are provided with relevant information for the promotion of their occupational health and safety activities.

At the Gunma Plant, we also provide support for overseas occupational health and safety activities through regular information sharing meetings on health and safety with Subaru of Indiana Automotive, Inc. and affiliated companies responsible for doing business overseas.

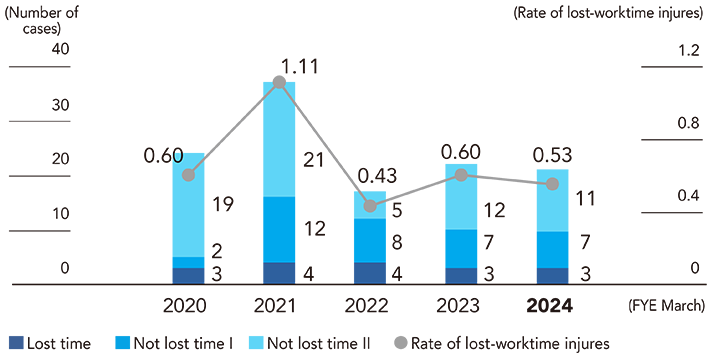

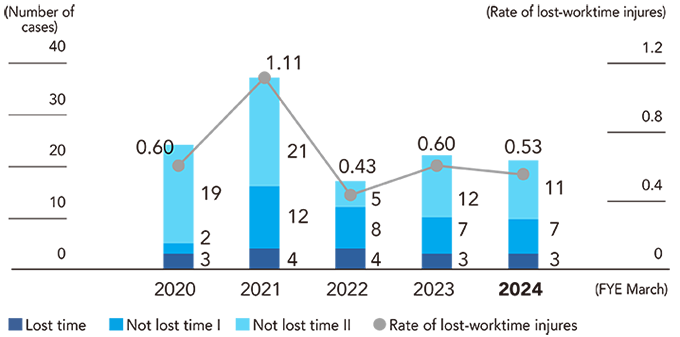

Targets and Metrics

With regard to industrial accidents and traffic accidents, we will continue to promote initiatives aimed at reducing the number of incidents (non-lost time/lost time injuries) and the frequency rate as key indicators.

Occurrence of Industrial Accidents and Accident Frequency Rate (SUBARU)

Initiatives

At the start of every fiscal year, SUBARU notifies managers and supervisors about the health and safety policies for the fiscal year through Health and Safety Committees at each site. This is so that all employees can share the health and safety activity targets and plans and raise their awareness about the prevention of industrial accidents, road safety, and health management.

Prevention of Industrial Accidents

Wearing of the Safety Declaration Badge

In order to elevate safety awareness among all SUBARU employees, each of us wears the safety declaration badge, on which it is clearly stated, “I always check for safety before performing any action.”

Promoting the Practice of Pointing and Calling

For the prevention of mistakes and human error, we urge employees at all our sites to practice pointing and calling at the crosswalks and other places on the premises as the basis for occupational health and safety, thereby raising their awareness about the importance of safe behaviors and increasing the accuracy of their safety checks.

Occupational Health and Safety Education

Hands-on Safety Dojo

At the Gunma Plant’s Hands-on Safety Dojo, the SUBARU Group is providing health and safety education not only to its own full-time and part-time employees, but also to temporary employees, employees of contractors and outsourcing companies working on our premises, employees involved in construction work on our premises, and employees of suppliers.

In FYE March 2025, approximately 3,400 employees annually participate in simulator safety training, reproducing conditions that would occur in the event of accidents such as a fall, cut, pinch, or entrapment. In addition, we are taking actions to cultivate hazard sensitivity by introducing employees to protective gear used in the field and teaching them the rules about equipment use from the time they join the Company.

Training Center

At the Gunma Plant, we provide health and safety education at the plant’s Training Center when employees begin assignments there.

The 10-day curriculum includes practical skills training using mock lines corresponding to trainees’ assigned processes, providing education to cultivate hazard sensitivity in an environment that allows trainees to visualize real disasters.

Approximately 2,000 employees participate in this education each year before assignment to their respective workplaces.

Health and Safety Slogan Contest

SUBARU invites all employees to submit safety slogans to be used in the following fiscal year with the aim of raising awareness of health and safety. Slogans are solicited under four themes: occupational safety, occupational health, traffic safety, and health management. In FYE March 2025, around 16,825 slogans were received.

Prevention of Industrial Accident Recurrence

As for industrial accidents and close calls that happened at our sites and affiliated companies, the department that has experienced the incident shall disclose related information to other departments on the premises and affiliated companies via the department in charge of health and safety at the site.

The main cause of industrial accidents in FYE March 2025 was decreased awareness of danger due to familiarity with work. Therefore, in FYE March 2026, we will promote back-to-basics safety activities to reinforce safety awareness, such as pointing and calling, personal safety declarations, and rigorous elimination of near misses.

At development and production sites, it is always necessary to improve productivity and take on challenges, but safety cannot be neglected. Going forward, we will continue to strengthen our daily accident prevention activities.

Road Safety

In order to prevent employees from getting involved in any traffic accidents while working, commuting, or enjoying their private time, we are implementing a range of measures as follows:

- Conduct awareness-raising activity, including introducing the cases of past accidents and showing a video on traffic safety, before the start of a long vacation, targeting all plant and site employees, many of whom commute by car.

- Organize a lecture by the chief of the local police station to improve employees’ driving manners.

- Provide new employees with hands-on road traffic safety training using actual vehicles in partnership with driving schools. Participants experience the risks of dangerous driving and traffic accidents firsthand, raising their awareness of accident prevention.

- Conduct psychological driving aptitude tests and use a driving recorder to help employees recognize their driving habits.

Unifying Initiatives at the Group Level

We have established the SUBARU Safety and Environment Council which we operate in collaboration with our business partners to ensure that all parties, including our Group companies in Japan, can strengthen health and safety in unison.

The council is especially active in strengthening and enhancing occupational safety, occupational health, traffic safety, and fire and disaster prevention, including through an annual general meeting, information sharing in the event of a disaster or traffic accident involving lost time injuries, and training for new employees, supervisors, and full-time managers.

Initiatives at Subaru of Indiana Automotive, Inc.

Since its inception, Subaru of Indiana Automotive, Inc. has been committed to workplace safety as a top priority alongside quality, and maintains one of the lowest occupational illness rates in the U.S. automotive industry. The company obtained ISO 45001 (occupational health and safety management systems) certification in August 2024 to provide employees with a safe and healthy working environment and prevent industrial accidents and illnesses.