Quality: Automotive Business

Our Approach

Quality is the foundation of “Enjoyment and Peace of Mind,” SUBARU’s core value. With “quality first” as our slogan, we are working to provide high-quality products and services.

Quality Policy

At SUBARU, quality is our highest priority as we earn the trust of our customers.

- We will deliver long-lasting products that our customers can use with peace of mind.

- We will continually improve our products and services by always listening closely to our customers’ voice.

- We will be a good corporate citizen in all markets where we do business by ensuring compliance with all internal rules, local laws, regulations and social norms.

Management System

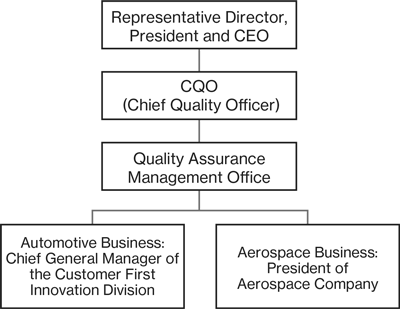

At the SUBARU Group, quality assurance activities for all Group companies and affiliates, both in Japan and overseas, are overseen by the CQO (Chief Quality Officer), with the President bearing ultimate responsibility. In addition, we have established a Quality Assurance Management Office to oversee and manage quality assurance. Under the purview of the CQO, the Chief General Manager of the Customer First Innovation Division oversees quality assurance activities for the Automotive Business, while the president of the Aerospace Company oversees quality assurance activities for the Aerospace Business. We have established a system that enables us to respond quickly and consistently to quality issues across the entire Group, thereby increasing the speed and effectiveness of global quality improvement.

Automotive Business

To meet the expectations and trust placed in us by customers regarding quality, we are working to provide high-quality SUBARU products and services that will impress our customers in all processes, from the product planning stage to procurement of parts from suppliers, production and shipping at factories, and after-sales service.

Quality Management System

We have established the Automotive Business Quality Manual based on ISO 9001 standards and have built and operated a quality management system (QMS). Since 2006, we have undergone audits by external audit organizations and have continuously obtained ISO 9001 certification. We aim to improve quality and customer satisfaction by assuring that products will comply with both customer requirements and applicable statutory and regulatory requirements, as well as by improving our operations.

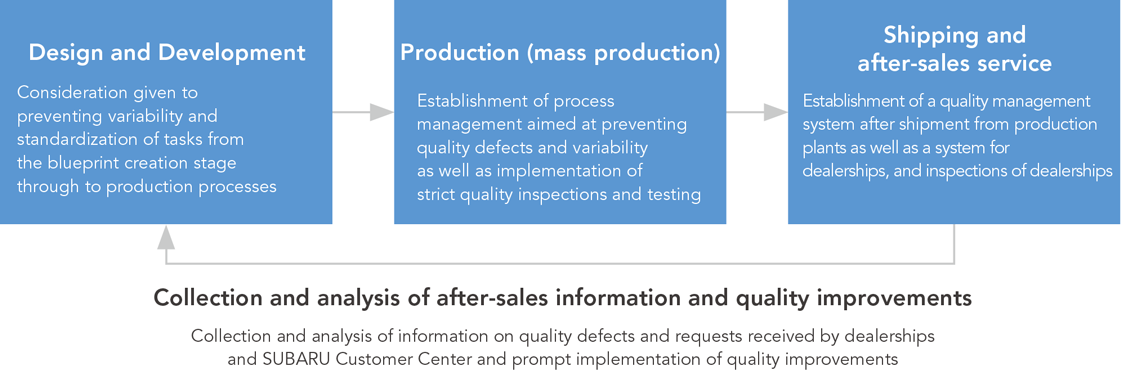

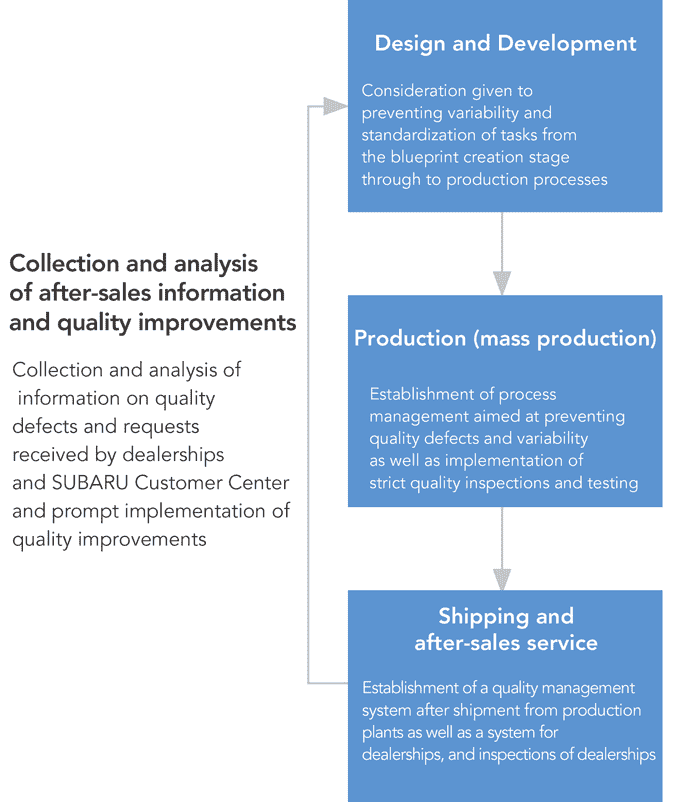

Quality Management Cycle

Quality Improvement Committee

The Quality Improvement Committee is the highest body for promoting quality improvement in the Automotive Business. It is attended by responsible persons in planning, development, procurement, production, sales, customer service, quality assurance, and other departments. Chaired by the Chief General Manager of the Customer First Innovation Division, the committee meets monthly in principle to discuss all quality issues related to all operations in the Automotive Business Unit. In addition to the above-mentioned departments, the North America Quality Improvement Committee meets on a semi-annual basis to discuss issues related to the North American market, and includes representatives from dealerships in the United States and Canada, as well as SUBARU’s North America plants.

Development Quality Assurance System

In order to deliver quality products to our customers, it is of utmost importance to improve quality at the point of development. To achieve this, we are strengthening the Innate Quality part of our Quality Enhancement activities that we launched in 2018, and are working to ensure quality throughout all vehicle development processes, from the initial planning and conceptualization stages to development, production, and distribution. We have compiled a database of defects that have occurred in the market in the past, and we conduct general inspections to ensure that measures to prevent their recurrence are incorporated into the vehicles we develop. These include identifying newly adopted parts and changes from vehicles produced in the past to prevent defects before they occur. In addition, the quality responsibilities of persons responsible for new vehicle development have been clarified and their authority has been strengthened. Furthermore, the development process puts stage gate management of quality targets first to enhance Innate Quality.

Manufacturing Quality Assurance System

At SUBARU, the customer-first principle is at the heart of all our factory operations as we strive for production at “the world’s highest quality, most efficient, clean, and comfortable factories.” The underlying concept of this desire is “own-process assurance.” In this concept, each process views the next process as the customer, aiming to deliver high-quality products to the end customer by assuring the quality of our own processes and preventing defective products from being passed on to the next process. We have established the Subaru Manufacturing Way (SMW) as our factory management philosophy, based on three pillars: own-process assurance; variable-mix, variable-volume, short-run production; and transfer of technical skills. Under the SMW, we are implementing Total Productive Maintenance (Management) (TPM) activities with the participation of all employees.

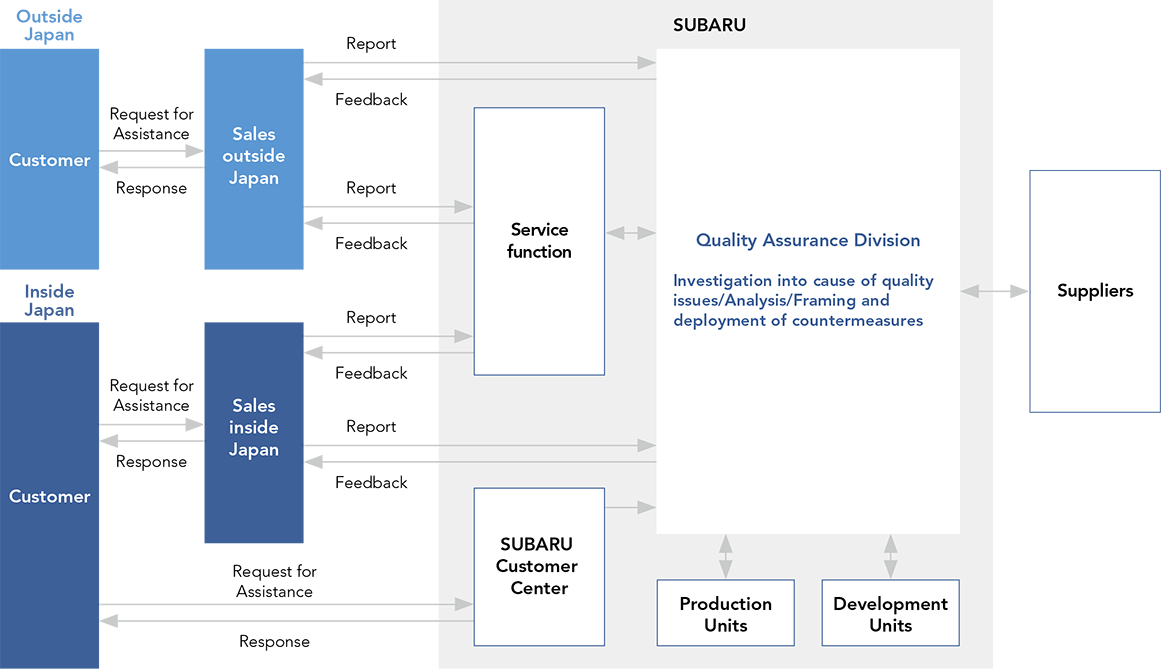

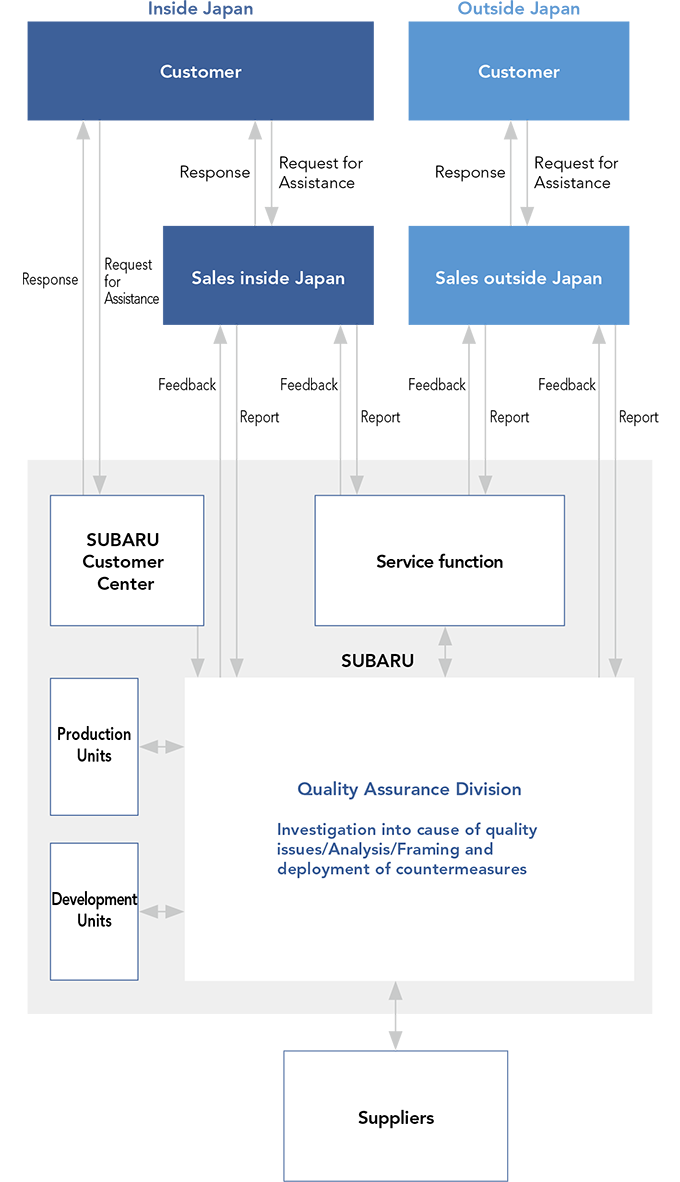

Market Quality Improvement System

The SUBARU Group aims to maintain a quality improvement system that quickly analyzes after-sales quality issues and customer requests to rapidly take measures and achieve higher-quality product development and production. Based on customers’ opinions collected from around the world, SUBARU works with the relevant in-house departments and suppliers in identifying quality issues, investigating their cause, and planning countermeasures.

For more details on our recall responses, please see ”Response to Recalls.”

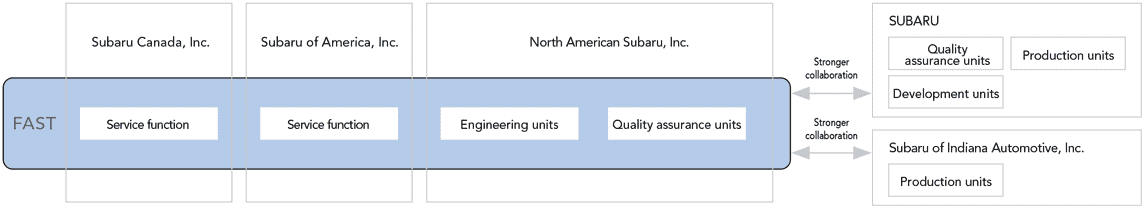

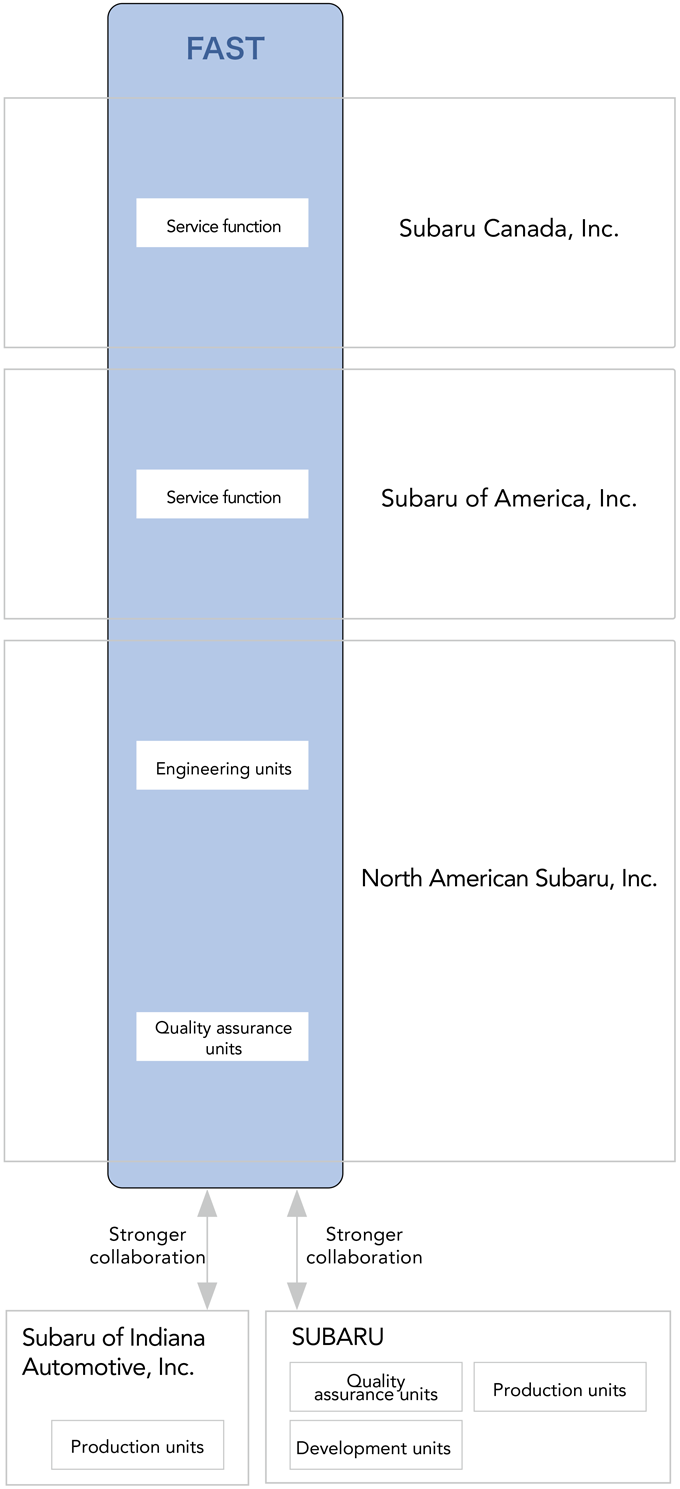

In January 2021, we established FAST (Fast Action & Solution Team), a North American quality improvement team where quality assurance and development units at local affiliated companies in the U.S. work together with service units at dealerships in the U.S. and Canada. By strengthening cooperation between departments, immediate decisions can be made on-site, and market demands can be met more speedily.

As of April 2025, SUBARU has integrated its Customer Service Division, Parts & Accessories Division, and Quality Assurance Division into a new Customer First Innovation Division. By integrating our after-sales service departments, we will further accelerate quality improvement and embody our customer-first principle.

Quality Improvement System

Structure of the FAST North American Quality Improvement Team

Collaborative System with Suppliers

In order to maintain and improve the quality of SUBARU vehicles, it is also important to ensure the quality of externally purchased parts. We are engaged in unified efforts with our suppliers to ensure the quality of externally purchased parts.

First, we have compiled standards and rules for building and ensuring stable quality into a manual, and by rolling it out to all of our suppliers and working to ensure that everyone understands and adheres to it, we are building a foundation on which both sides can work together based on a common understanding. In addition, we hold annual briefing sessions on our Quality Policy for suppliers at the beginning of each fiscal year to share information about quality-related situations. Furthermore, we have set quality targets and key quality indicators, and we present quality improvement measures, key points for enhancing quality, and other information as concretely as possible. Furthermore, by following the Advanced Product Quality Planning (APQP) process, our activities also encourage our suppliers to make their own improvements, contributing to overall quality improvement.

In recent years, where the external environment has become extremely uncertain amid large-scale natural disasters, shifting world affairs, and other developments, parts supplies issues have become more likely. Amid this situation, we have also established support systems for our suppliers in order to help quickly restore parts supplies in the event of an emergency.

In addition, we conduct quality checks and confirmations regarding environmental and human rights issues for our suppliers, and introduce these initiatives in information about our CSR procurement.

Approach to Risks and Opportunities in Quality Assurance

Quality is an important element directly related to the survival of a company. While providing high-quality products enhances the credibility of the SUBARU brand, defects that reach the market bring us face-to-face with the risk of loss of customer confidence, a risk that can cause tremendous damage to corporate finances and reputation. Therefore, it is essential to continuously maintain and improve quality, and we believe that improving the quality of each employee’s work will lead to the improvement of SUBARU’s quality.

SUBARU conducts internal training on quality and holds events called Quality Caravans every year. Quality Caravans are conducted with the aim of fostering quality awareness through an accurate understanding of the current state of quality at SUBARU. In addition, internal audits are conducted by qualified employees to check that business is being conducted properly. We then undergo an audit by an external auditing organization to ensure our continued ISO 9001 certification.

As for our suppliers, we support regular voluntary audits of quality assurance systems and quality management systems and provide advice from a third-party perspective. In addition to regular audits, SUBARU directly observes suppliers’ manufacturing processes and production sites. Here, we conduct audits and process checkups on an ad-hoc basis, offer proposals for productivity improvement, and otherwise engage collaboratively to further improve quality.

As a result of these quality maintenance and improvement activities, SUBARU ranked first among 22 automakers in the 2024 reliability evaluation (for new vehicles up to the third model year) by Consumer Reports in the United States, and also ranked first among 32 companies in the overall brand evaluation, which includes performance evaluations.

Initiatives

Quality Assurance Training

In order to deliver high quality products to our customers, we believe it is important for each and every employee to work with an awareness of quality. The SUBARU Group provides quality education to all employees. Quality education is provided on an ongoing and regular basis tailored to employee knowledge and experience levels, including their year of entry into the Company and their position. This instills a customer-centric, quality-first awareness, educating each and every employee so that they put quality first in their actions.

We also recognize cases at our automotive manufacturing business units where a heightened focus on quality has resulted in the prevention of issues with a quality excellence award. Information on award recipients and their achievements is disseminated throughout SUBARU via the intranet and other platforms.

Global Quality Meeting

In order to steadily implement our quality-first philosophy, the SUBARU Group places great importance on dialogue with our dealerships around the world, who are in direct contact with our customers on a daily basis. Through technical liaison meetings held twice a year for the Japanese market, main dealerships service meetings held once or twice a year in overseas markets, and block conferences held in six regions,* we make decisions on matters such as optimum means of addressing quality problems that inconvenience our customers, while incorporating the views of dealerships. In FYE March 2026, these meetings are to be held in a combination of on-site and web-based sessions.

In addition, in order to listen to the voice of the market and speed up quality improvement, the Quality Improvement Committee, chaired by the Chief General Manager of the Customer First Innovation Division, holds meetings on a monthly basis (in principle) to discuss quality at the executive level in all departments. Furthermore, the North America Quality Improvement Committee, which is comprised of the North America CQO and heads of North American subsidiaries, focuses on quality in the North American market and is held several times a year.

- *

- Six regions refers to the CIS, Central Europe, Northern Europe, Southern Europe, Oceania, and Central and South America. Block conferences are held in a country in each of these regions. Their participants include representatives from dealerships’ service departments and expatriates working in the region.

Quality Caravan

Since FYE March 2019, we have been holding an annual event called the Quality Caravan for all SUBARU employees to inform participants about the quality status of SUBARU products and customer feedback. In FYE March 2025, these were held for a total of 42 days, including the following activities.

- Presentation of recent quality issues from the customer’s perspective

- Presentation of interview videos with customer call center staff in Japan

- Presentation of videos explaining how cars are used in North America, presented by the president of a North American dealership

Pre-Shipment Inspection

At SUBARU, rigorous inspections are conducted before shipment to prevent any defects from leaving the facility. In 2018, the operation of vehicle inspections was spun off from the traditional manufacturing organization to form the Vehicle Inspection Department under the Quality Assurance Division (currently the Customer First Innovation Division) in order to ensure thorough inspections from a customer perspective. In addition, we set up two new facilities for final vehicle inspections to establish an environment conducive to accurate inspections through clearly defined processes. The first facility started operations in August 2022, with the second becoming operational in August 2023. We provide environments with standardized lighting facilitating easier detection of anomalies and inspection processes at undercarriage using a lowered floor. We conduct rigorous inspections in these environments utilizing digital technologies, aiming to deliver high-quality products that customers can use with peace of mind.

Investigation of Defective Parts

SUBARU set up the Quality Assurance (QA) Lab to internally investigate defective parts for the swift resolution of any issues that arise. In the event of a defect, development and manufacturing departments lead efforts to determine causes and implement solutions. In cases where pinpointing the cause is especially difficult, quality assurance units expedite defect resolution by conducting independent analysis and investigation of defective parts in the QA Lab.

Response to Recalls

The SUBARU Group takes measures to cope with recalls in order to prevent accidents, in accordance with our highest priority placed on customer safety.

We have established the Recall Committee to determine specific measures to be taken in the event of product defects that can infringe on safety or laws and regulations. This committee is chaired by the CQO, and was established based on customer suggestions and defect information from around the world and in accordance with internal regulations. Any recalls are promptly reported to the relevant authorities. Affected customers are contacted by direct mail and other methods from our dealerships to encourage them to have their car repaired free of charge, with their safety and peace of mind as our top priority. We monitor the progress of market measures to ensure that improvements can be made quickly.

As of April 2025, SUBARU had no cases of violating laws and in-house regulations in regard to information provision on quality and safety.

At SUBARU, we are advancing “parts traceability” by linking the individual vehicle number with the individual part number. In the unlikely event of a recall, we strive to minimize the impact on our customers and shorten the response time by quickly and accurately identifying vehicles equipped with defective parts, thereby reducing the scope of the defect and accelerating our response.

Recalls of SUBARU Cars

(Number of units: Thousand units)

| FYE March 2021 | FYE March 2022 | FYE March 2023 | FYE March 2024 | FYE March 2025 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Number of Cases | Number of Units | Number of Cases | Number of Units | Number of Cases | Number of Units | Number of Cases | Number of Units | Number of Cases | Number of Units | |

| Japan | 8 | 177 | 9 | 311 | 13 | 391 | 13 | 359 | 5 | 47 |

| North America | 5 | 217 | 7 | 1,380 | 11 | 378 | 11 | 304 | 1 | 22 |

| Other | 2 | 6 | 6 | 376 | 9 | 266 | 12 | 40 | 3 | 8 |

| Total | 15 | 400 | 22 | 2,067 | 33 | 1,035 | 36 | 703 | 9 | 77 |

Note:

- 1.

- Information presented is internal data and may differ from data published by the respective authorities.

- 2.

- Identical recalls conducted across multiple countries/regions are combined to count as one recall.

- 3.

- Number of recalls includes those for OEM vehicles.

Takata Airbag Recall Progress

SUBARU’s recall progress related to the Takata airbag recall exceeds the industry average of 88.2% in the U.S.

Takata Airbag Recall Progress in the U.S.

| No. | Automotive manufacturer | Progress |

|---|---|---|

| 1 | U.S. company A | 99.4% |

| 2 | European company B | 98.1% |

| 3 | Japanese company C | 95.7% |

| 4 | Japanese company D | 95.3% |

| 5 | Japanese company E | 95.0% |

| 6 | U.S. company F | 94.8% |

| 7 | Japanese company G | 94.8% |

| 8 | European company H | 93.9% |

| 9 | SUBARU | 93.4% |

| 10 | European company J | 93.4% |

| ・・・ | ・・・ | |

| Industry average | 88.2% |

- Note:

- From National Highway Traffic Safety Administration (NHTSA) data published April 2024.