Coexistence with Nature

Our Approach

With the automotive and aerospace businesses as the pillars of SUBARU’s operations, our fields of business are the earth, the sky and nature. The SUBARU Group’s vision for the environment is to “Cherish and protect the environment— the earth, the sky and nature—through Group-wide activities.” We have identified coexistence with nature as one of our important environmental themes and set a direction to aim for zero effective impact on the natural environment.

Furthermore, the SUBARU Group instituted the SUBARU Guidelines on Biodiversity in April 2019, which serve as the basis for its approach to biodiversity. The guidelines were formulated with reference to the government’s Guidelines for Private Sector Engagement in Biodiversity (Ministry of the Environment) and the Declaration of Biodiversity by Keidanren: Guide to Action Policy, as well as by taking into account international trends in biodiversity management, in order to ensure that their effectiveness and continuity can be guaranteed.

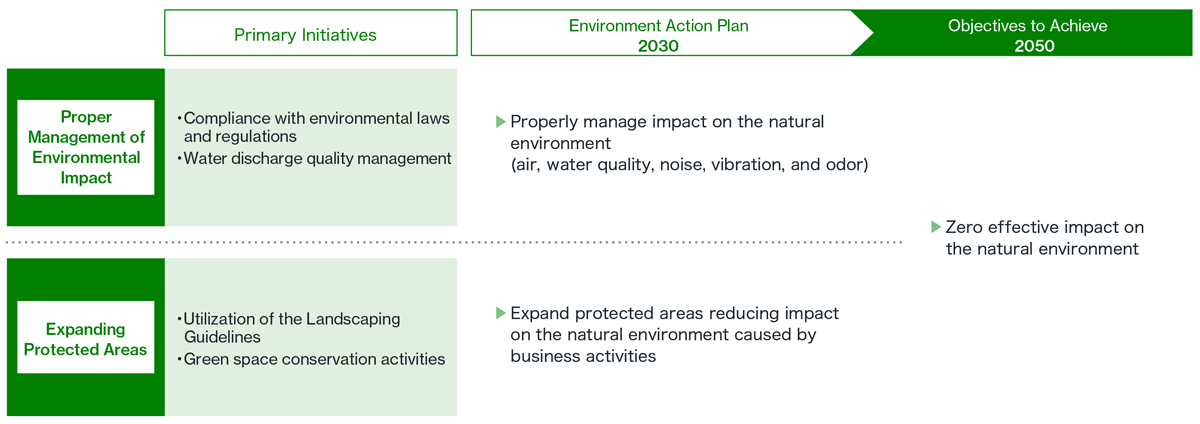

Coexistence with Nature: Roadmap

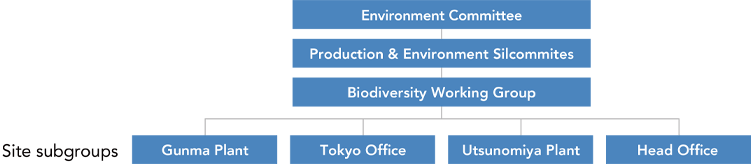

Management System

Efforts related to the medium-term goals of proper management of environmental impact and expansion of nature conservation areas on owned land are managed by the Pollution Prevention Working Group and the Biodiversity Working Group, which are subordinate organizations of the Production & Environment Subcommittee. These efforts are regularly reported to the Environment Committee to manage the progress of initiatives related to the Environment Action Plan.

Organizational Structure for Coexistence with Nature

Medium-Term Goals

The SUBARU Group has revised its Environment Action Plan 2030 in line with the three newly established priority themes. We have identified coexistence with nature as an environmental theme of particular focus and have set a target of zero effective impact on the natural environment by FYE March 2051. In business activities that are eligible for efforts to reduce impact on the natural environment, we are focusing on proper management of environmental impact and expansion of nature conservation areas on owned land. Given this, we have newly set forth two medium-term goals to be achieved by FYE March 2031: proper management of environmental impact on the natural environment (air, water quality, noise, vibration, and odor) at business sites, and expansion of protected areas reducing impact on the natural environment caused by business activities.

Proper Management of Environmental Impact

Compliance with Environmental Laws and Regulations and Related Initiatives

In addition to complying with environmental laws and regulations, SUBARU has set its own voluntary environmental standard values, which are 20% stricter than the regulatory values set by law. We are committed to never exceeding the regulatory and voluntary thresholds and striving to achieve the goal of zero environmental complaints and zero environmental accidents. In FYE March 2025, one air-related, three water quality-related, and one noise-related violations of statutory standards were confirmed at the Gunma Plant, while two water quality-related and one noise-related violations of statutory standards were confirmed at the Utsunomiya Plant. For these issues, we are identifying the causes through equipment inspections and exploring and implementing countermeasures and improvements, such as introducing measurement instruments and modifying systems.

In addition, we identify the causes of environmental accidents that occur on and off our premises and environmental complaints we receive, and strive to prevent their recurrence.

Compliance with Environmental Laws and Regulations and Major Results in FYE March 2025

| Number of Cases | |

|---|---|

| Violations of laws and regulations | 8 |

| Environmental accidents (emissions into the environment) | 3 |

| Environmental accidents (emissions on-site) | 8 |

| Environmental complaints | 4 |

Noise, Vibration, and Offensive Odors

The Gunma Plant conducts daily patrols premised on the fact that people and measuring instruments respond to odors and noise very differently, and we are continuing our efforts to improve production facilities, among others.

Soil and Groundwater

We started our voluntary soil and groundwater tests at our locations in 1998 and have since implemented purification measures and groundwater monitoring as required. Since the Soil Contamination Countermeasures Act came into effect in 2003, we have also filed reports and conducted tests in accordance with the law.

PCB Waste

SUBARU is auditing and treating polychlorinated biphenyl (PCB) waste as planned. We are currently conducting a final survey of the status of PCB waste treatment at each SUBARU base and at Group companies and Dealerships in Japan, and the SUBARU Group plans to complete the disposal of PCB waste by FYE March 2028.

Hazardous Waste

SUBARU has had no significant spillage, nor has it transported waste deemed hazardous under the terms of Annex I, II, III, and IV of the Basel Convention*.

- *

- International treaty on the control of movements of hazardous wastes between nations and their disposal procedures

Water discharge quality management

Gunma Plant

At the Gunma Plant, wastewater is treated and then discharged into rivers after passing through an oil-water separation tank, where it eventually merges into the Tone River. Appropriate wastewater treatment is provided to ensure the water after it merges into the Tone River is safe during use for agricultural and domestic purposes in the downstream areas.

Utsunomiya Plant

In the Utsunomiya area, after treating wastewater from surface treatment processes we discharge it into the sewer system, and discharge rainwater and cooling water into the river after checking its quality in the final water quality monitoring tank. In addition, we dispose of wastewater from the painting process in the Handa area as industrial waste, and treat domestic wastewater in septic tanks prior to discharging it into Kinuura Port and the Agui River.

Stormwater Management (Subaru of America, Inc.)

Subaru of America, Inc. (SOA) is addressing the risk of flooding on its premises by raising existing site grades by up to approximately 1.5 meters and planting wetland vegetation in areas with poor drainage, taking into account the importance of stormwater management.

Its Subaru rain garden plays a role in mitigating the risk of flooding in the nearby Cooper River by temporarily storing stormwater.

Business Activity and Coexistence with Nature

SUBARU supports the Declaration of Biodiversity by Keidanren (Japan Business Federation) and has established the SUBARU Guidelines on Biodiversity to continue business activities with consideration for biodiversity, including efforts such as the SUBARU Forest conservation initiative.

SUBARU Guidelines on Biodiversity

Our society is supported by biodiversity, which is the source of various blessings from nature.

On the other hand, “biodiversity” is rapidly being lost on a global scale.

We promote biodiversity preservation through our business activities and contribute to the environmental protection of our planet while aiming to coexist with the earth, the sky and nature.

- We grasp the impact of business activities on biodiversity and reduce their impact. We also promote initiatives leading to further recovery.

- We strive to raise awareness of biodiversity.

- We respect international rules concerning biodiversity.

- We cooperate with stakeholders and strive for preservation of biodiversity.

- We proactively disclose information on activities regarding biodiversity.

Established in April 2019

Landscaping Guidelines

SUBARU has formulated the Landscaping Guidelines, in the belief that in order to establish itself in a community and conduct business activities while being loved by community members, it is necessary to be mindful of the environment, history, and climate of each community and aim to create sites that are well-rooted locally. The Landscaping Guidelines stipulate that in addition to the procedures for formulating planting lists, each site must follow the three principles for the prevention of damage by invasive alien species set forth by the Ministry of the Environment, namely “do not introduce, release, or spread” in order to conduct business activities that do not have a negative impact on biodiversity.

Procedures for Formulating Planting Lists from the Landscaping Guidelines

- Formulate a planting list from species endemic to the area around the site, referring to plants in facilities that have maintained nature since ancient times, such as shrines, temples, and natural parks in the surrounding area, as well as guidelines and lists issued by each local government for selecting native species as available.

- If it is difficult to formulate a planting list of species endemic to the area around the site, a planting list should be formulated based on plants other than those listed as invasive alien species as published by the national government and local governments.

- Formulate a planting list from plants selected in the first two steps. Consider consulting with construction companies when formulating this list.

Sites Conducting Planting Activities Based on the Landscaping Guidelines and Their Initiatives

| Site | Initiative Overview |

|---|---|

| Kitamoto Plant, Gunma Plant | When planting in the vicinity of the plant building’s entrance, we selected mixed shrubbery based on the Landscaping Guidelines. |

| Oizumi Plant, Gunma Plant | When planting in the vicinity the new cafeteria and office building, we selected plants with a focus on mixed shrubbery and ground cover plants taking into consideration the appropriate density of tall and medium-height trees plus shrubbery based on the Landscaping Guidelines. |

| Tokyo Office | At the Tokyo Office, we maintain and manage bamboo-leaf oak, East Asian beautyberry, and other species native to the Musashino area within the office’s premises to enhance the landscape and biodiversity. |

| Utsunomiya Plant | When planting trees during the construction of the administration building, native Japanese species were selected based on the Landscaping Guidelines. |

Initiatives for Coexistence with Nature

Donations to fund environmental conservation activities at Matsuyama Marsh

SUBARU has utilized the corporate version of a hometown tax donation program—the government’s tax incentive scheme to encourage companies to support regional revitalization—to donate to the Hokkaido government’s Matsuyama Marsh* Forest Project, primarily for boardwalk improvements in Matsuyama Marsh. With this donation, the aging information boards and walking paths were improved.

- *

- Matsuyama Marsh (Bifuka Town): Japan’s northernmost high-altitude wetland situated 797 meters above sea level. As the marsh is home to around 200 distinctive plant species, including ferns and mosses, the Ministry of the Environment has selected it as one of Japan’s 500 most important wetlands

Greenery Conservation and Creation

Since the SUBARU Group’s business locations are closely linked to the neighboring natural environments and ecosystems, we make a variety of contributions to the conservation of biodiversity in each area.

SUBARU Forest Bifuka in Hokkaido

In a forest of approximately 115 hectares located on the premises of SUBARU Test & Development Center Bifuka Proving Ground, SUBARU started forest management and conservation activities in FYE March 2018, including tree-planting, thinning, and nature conservation. We aim to carry out these activities in collaboration with local communities such as Bifuka Town with a long-term plan to create a forest through artificial afforestation in 50 years. In FYE March 2025, we conducted a literature survey on wild animals and plants (plants, mammals, birds, amphibians, reptiles, insects, aquatic animals, and terrestrial mollusks) that are likely to inhabit or grow in the surrounding area, and identified approximately 1,280 species.

Along with utilizing wood from thinning during forest maintenance projects as biomass fuel, we have also been purchasing J-Credits (BIFUKA AIR Bifuka Town Forest Credits) since FYE March 2022 in line with climate change countermeasures. In addition, as of FYE March 2020, Bifuka Town has acquired the international SGEC-FM forest certification* for town-owned forests, including SUBARU Forest Bifuka, in order to achieve effective use of forest resources.

- *

- Forest Management Certification by the Sustainable Green Ecosystem Council (SGEC)

Sponsorship of a Tree-Planting Ceremony at Bifuka Town

In 2018, Bifuka Town and SUBARU signed an agreement on implementation of forest conservation activities in order to carry out tree planting, forest thinning, nature conservation, and other activities in a forest of about 115 hectares on the SUBARU Test & Development Center Bifuka Proving Ground site as part of SUBARU Forest Project activities, as well as to conduct activities in partnership with local communities. As part of these activities, SUBARU sponsors an annual tree-planting ceremony. In FYE March 2025, 350 clean larch trees were planted as part of this ceremony.

SUBARU Friendship Forest Akagi in Gunma

In April 2018, SUBARU obtained the naming rights to a prefectural forest park in Gunma Prefecture, where its automotive plants are located, renaming the park—once called Gunma Prefectural Akagi Forest Park—"SUBARU Friendship Forest Akagi” and supporting the conservation and maintenance of the prefectural forest. Based on the SUBARU Friendship Forest Akagi Forest Management Project Agreement signed in 2023, support was provided for forest management activities such as thinning and the development of walking trails. In recognition of these efforts, a ceremony was held in September 2024 to present SUBARU with a letter of appreciation for its donations to the forest management project.

On the day of the presentation ceremony, the 2024 Mt. Akagi Painting Workshop & Drum Circle was held at SUBARU Friendship Forest Akagi (Gunma Prefectural Akagi Forest Park). SUBARU also supported this event and co-sponsored a thinned wood coaster workshop, which was attended by a total of 173 people over two days.

Kitamoto Plant, Gunma Plant

The Kitamoto Plant in Kitamoto City has been nurturing and taking care of cherry trees growing on the site since they were received from the city in 2003. The trees are descendants of the Ishito Kabazakura cherry tree, estimated to be 800 years old, at Tokoji Temple in the city. Ishito Kabazakura was designated as a natural monument of Japan in 1922 and is classified as one of Japan’s five great cherry trees.

Oizumi Plant, Gunma Plant

Ecological surveys (birds, mammals, plants, aquatic organisms, and insects) were conducted in a reservoir area and open ditches at the Oizumi Plant. The survey results showed that the wetland and aquatic environments are maintained throughout the year, and successfully identified several important and desirable species for conservation. Based on the survey results, we will continue to manage the site based on the maintenance and preservation of the existing wetlands and aquatic environment, and aim to register the site as a Nationally Certified Sustainably Managed Natural Site.

Tokyo Office

At the Tokyo Office, we maintain and manage bamboo-leaf oak, East Asian beautyberry, and other species native to the Musashino area within the office’s premises to enhance the landscape and biodiversity. We also participate in activities to protect the natural features of the region and share opinions with industry, government, academia, and the private sector.

Overseas

Subaru of Indiana Automotive, Inc.

Subaru of Indiana Automotive, Inc. (SIA) has developed water retention areas and surrounding green spaces on plant premises with consideration for local wildlife habitats. As a result, wild Canada geese and herons use this area for feeding and resting, and a significant population of deer also resides in and around the plant site, which is surrounded by a rich natural environment. In 2003, the National Wildlife Foundation designated the site as a supportive wildlife habitat, marking the first such designation for an automotive production plant in the U.S.

Subaru of America, Inc.

The SOA headquarters building has acquired silver LEED certification, with environmentally friendly planting incorporated into its environmental protection efforts. Specifically, the site features a Pennsylvania Horticultural Society-designed landscape including native perennials, hardwoods, and grasses to create a drought-resistant location. This well-maintained landscape provides a diverse habitat for wildlife. The company has also introduced stormwater management initiatives, such as raising construction site grades, planting wetland species in areas with poor drainage, and installing a rain garden.

Pollinator Garden (North American Subaru, Inc.)

North American Subaru, Inc. has replaced a portion of the grassy plot on its premises with a pollinator garden of approximately 10,117 m2 in size. The goal of the Pollinator Garden is to create a natural planting garden that supports the work of pollinators (insects and other pollen carriers) and enhances their habitat. Additionally, by establishing this natural planting, the need for pesticides is eliminated, and this initiative is expected to save approximately 170 m3 of water per year.

Other Key Initiatives

Natural Life

With its DNA as an aircraft manufacturer, SUBARU has always prioritized safety and focused attention on protecting life with an approach based on People-oriented Monozukuri. We have launched the Cherishing Every Life Project as an initiative that centers on this approach to expand our activities together with our customers and local communities. Under the project’s two themes of human life, which is irreplaceable, and natural life, which is rich forests and animal life, we are engaged in activities to support people who, like us, have a strong belief in the protection of life and are working day by day to protect and connect life to a future full of happiness.

As part of our initiatives for natural life, we have formed partnerships with the Shiretoko Nature Foundation, the Yakushima Environmental and Cultural Foundation, and the Natural Parks Foundation to support conservation activities in the World Heritage Sites of Shiretoko and Yakushima, as well as in 15 national parks across Japan, with the aim of passing on nature to future generations. For details on each activity, please visit our dedicated website page about this project.

Cherishing Every Life Project (Japanese version only)

TOPICS

Topic Support for the Natural Parks Foundation, Tottori Branch, Mt. Daisen Project Area through the Natural Life Side of the Cherishing Every Life Project

The Daisen-Oki National Park Mt. Daisen Project Area has been provided with patrol cars by SUBARU CHUSHIKOKU CORORATION, a SUBARU dealership, to support the foundation’s activities. These funds are used for managing park facilities in the Daisen Masumizu Highland, removing invasive plants that have entered the special protection zone of the national park, conducting awareness campaigns and patrols to prevent illegal collection of plants and animals within the park, and collecting litter.

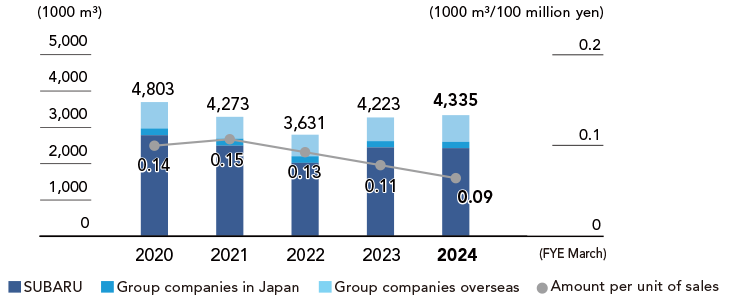

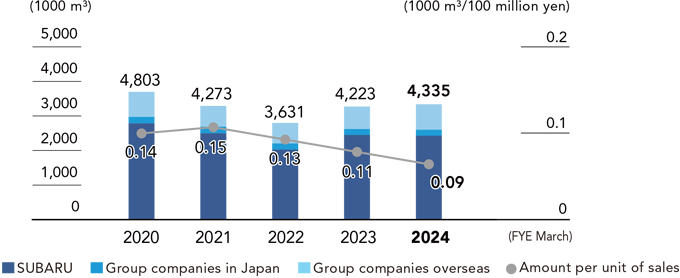

Water Resource Management

The Production & Environment Subcommittee manages the SUBARU Group’s water usage at each site, and both the total amount and amount used per unit of sales are maintained at a constant level.

In addition, the SUBARU Group has conducted a water risk survey of its major business locations and found no high water risk at any location. We will continue to conduct periodic water risk surveys as well as promote initiatives to reduce water consumption.

Water Risk

The SUBARU Group uses a third-party expert to implement water risk assessments to ensure the sustainable use of water. In FYE March 2024, we conducted an in-house water risk assessment using the World Resources Institute (WRI) Aqueduct Water Risk Atlas and WWF-DEG Water Risk Filter, confirming that water risk is generally below moderate, consistent with past surveys.

In addition, the SUBARU Group carries out disaster risk response for its business partners in Japan. When organizing the system for restoration support activities in the event of a contingency at our suppliers, we have also introduced a system to share information on disaster risks to both parties.

Water Consumption

Scope

SUBARU:

Gunma Plant, Tokyo Office, Utsunomiya Plant, Ebisu Subaru Building, Accessory Center, SUBARU R&E Center (SKC), SUBARU R&E Center Bifuka Proving Ground, SUBARU Training Center

Group companies in Japan:

Yusoki Kogyo K.K., Fuji Machinery Co., Ltd., Ichitan Co., Ltd., Kiryu Kogyo Co., Ltd., Subaru Logistics Co., Ltd., HBC Co.,Ltd.

Overseas Group companies:

Subaru of Indiana Automotive, Inc., Subaru of America, Inc., Subaru Canada, Inc., North American Subaru, Inc.

Water Consumption by Source (Thousands of m3)

| Scope | Tap Water | Industrial Water | Groundwater FYE March 2025 | Source of Water Intake |

|---|---|---|---|---|

| Japan | 427 | 2,448 | 604 | Tone River, Watarase River |

| North America | 962 | 0 | 0 | Groundwater from the Teays Valley aquifer |

| Total | 1,389 | 2,448 | 604 |

Scope

Japan:

Gunma Plant, Tokyo Office, Utsunomiya Plant, Yusoki Kogyo K.K., Fuji Machinery Co., Ltd., Ichitan Co., Ltd., Kiryu Kogyo Co., Ltd., Subaru Logistics Co., Ltd., HBC Co.,Ltd.

North America:

Subaru of Indiana Automotive, Inc., Subaru of America, Inc., Subaru Canada, Inc., North American Subaru, Inc.

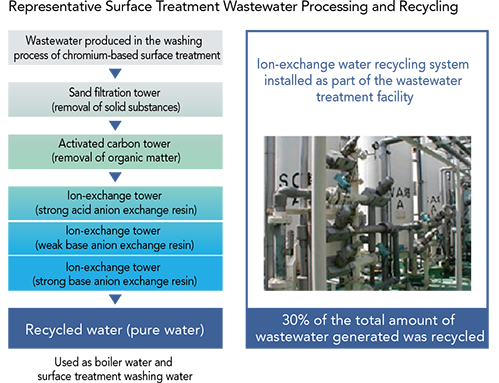

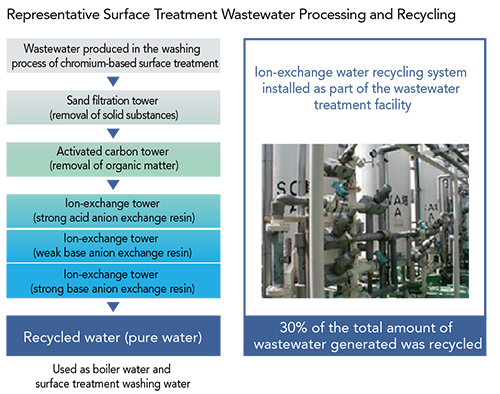

Utsunomiya Plant

The Utsunomiya Plant has introduced a surface treatment facility equipped with an ion-exchange water recycling system that converts wastewater into pure water. In FYE March 2025, 24,243 m3 (15.3%) of the total of 158,048 m3 of water used in the surface treatment facility was recycled and utilized at the plant as washing water for the facility.

Representative Surface Treatment Wastewater Processing and Recycling

Initiatives for Paper Use

SUBARU is taking actions to go paperless by fully digitizing payment guides for our business partners to be available online and achieving paperless processing of internal accounting documents related to maintenance parts and vehicle accessories. In addition, Subaru of America, Inc. is working to reduce paper usage through the use of FSC-certified paper and the introduction of electronic platforms.

Forest Conservation Through FSC-Certified Paper (Subaru of America, Inc.)

SOA uses Forest Stewardship Council (FSC) certified paper whenever possible. FSC-certified paper is recognized for its role in promoting activities that protect forests, such as maintaining their stable carbon storage volumes.

Paperless Initiatives through Introduction of DocuSign (Subaru of America, Inc.)

Subaru of America, Inc. has introduced the DocuSign electronic signature service to move away from its traditional paper-based business style and establish a system that allows all procedures, such as contracts and approvals, to be completed online. By utilizing DocuSign, we were able to reduce paper usage by approximately 223,000 sheets in FYE March 2025.

Emission of VOCs/Chemical Substances Regulated by the Pollutant Release and Transfer Register (PRTR) Act and NOx and SOx Emissions

VOC

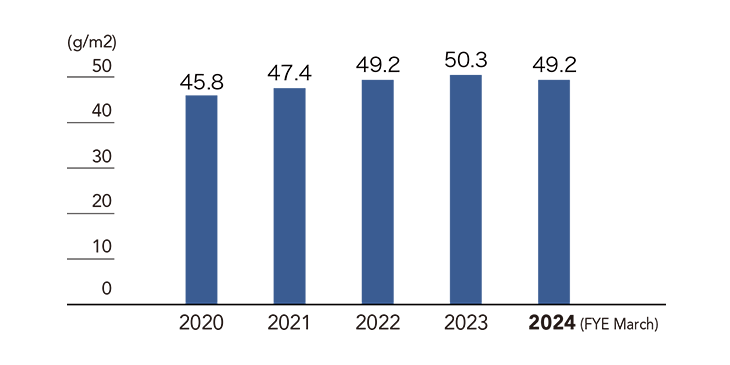

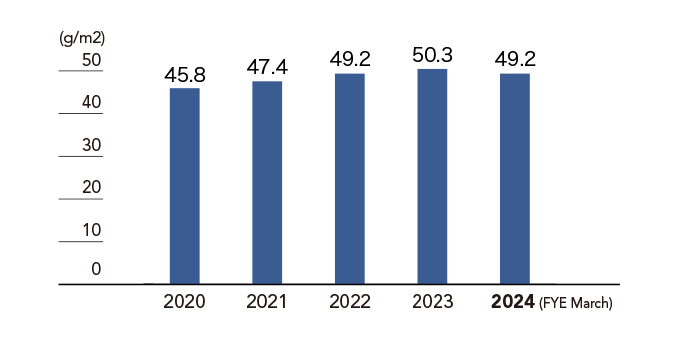

SUBARU manages volatile organic compounds (VOCs) emissions during the automobile painting process using an emissions per unit coating area calculation method. FYE March 2025 emissions increased 1.4% compared with the previous fiscal year to 49.9 g/m2. We are reducing the amount of cleaning thinner used in the automobile painting process and increasing recovery as a measure to reduce VOC emissions during painting.

In the automobile coating processes at Subaru of Indiana Automotive, Inc., an ad-hoc upgrade was made to painting robots equipped with high-efficiency applicators, contributing not only to improved quality but also to reduced paint sludge and VOC emissions.

VOC Emissions During the Automobile Painting Process

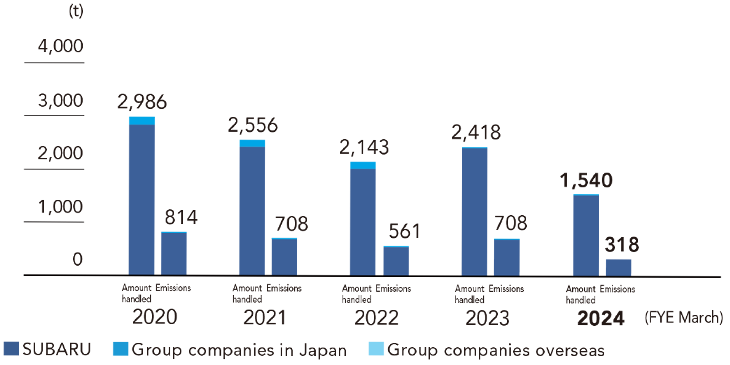

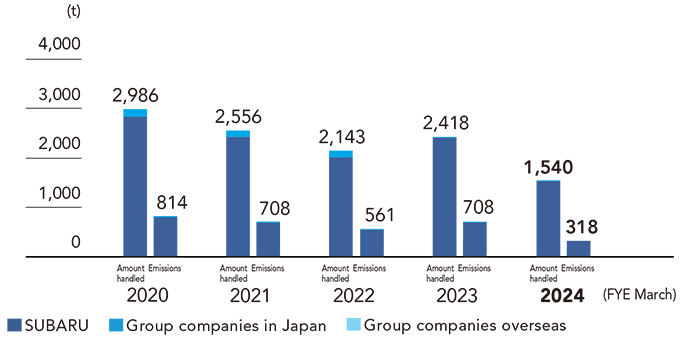

Chemical Substances Regulated by the Pollutant Release and Transfer Register (PRTR) Act

Scope

SUBARU: Gunma Plant, Tokyo Office, Utsunomiya Plant

Group companies in Japan:

Yusoki Kogyo K.K., Fuji Machinery Co., Ltd., Ichitan Co., Ltd., Kiryu Kogyo Co., Ltd., Subaru Logistics Co., Ltd., Fuji Aviation Maintenance Co., Ltd.

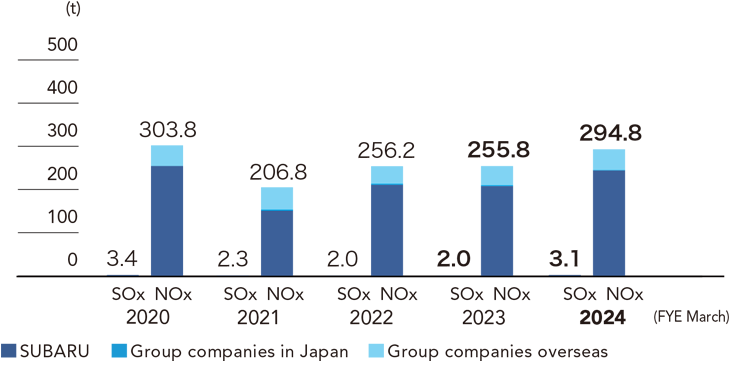

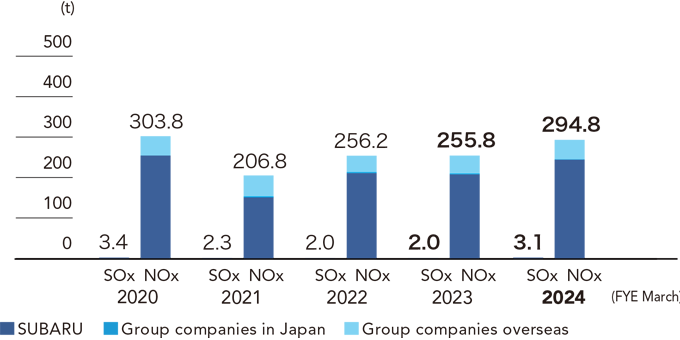

NOx and SOx Emissions

Scope

SUBARU: Gunma Plant, Tokyo Office, Utsunomiya Plant

Group companies in Japan:

Yusoki Kogyo K.K., Fuji Machinery Co., Ltd., Ichitan Co., Ltd., Kiryu Kogyo Co., Ltd., Subaru Logistics Co., Ltd.

Overseas Group company:

Subaru of Indiana Automotive, Inc.