Realizing a Circular Economy

Our Approach

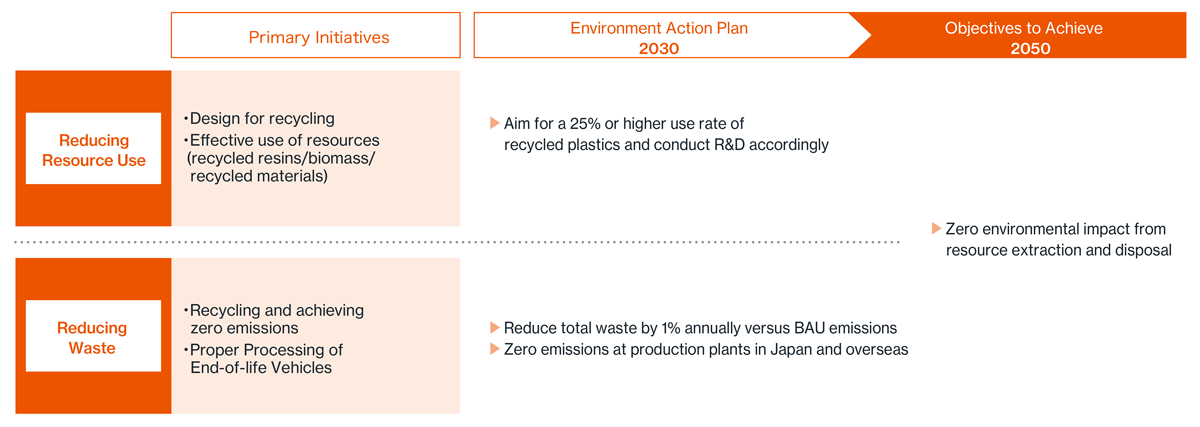

The SUBARU Group considers it very important for manufacturing companies to help realize a society where materials are recycled continuously and the sustainability of business is assured through recycling to maximize resource efficiency. Therefore, we have established “Realizing a Circular Economy” as an important environmental theme. Furthermore, we have set zero environmental impact from resource extraction and disposal as our target for FYE March 2051, and have established an Environment Action Plan 2030 with medium-term goals to be achieved by FYE March 2031.

Roadmap for Realizing a Circular Economy

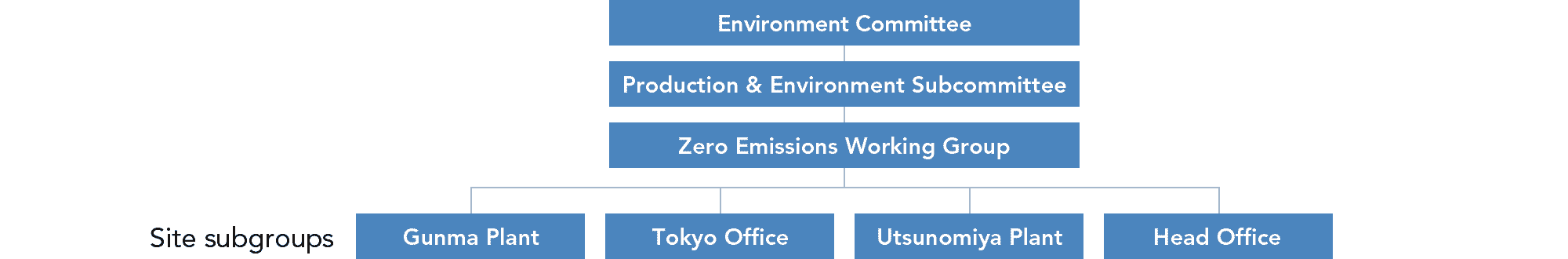

Management System

Circular Economy-related Management Organization

Medium-Term Goals

Furthermore, we have set the target of proceeding with research and development with the goal of using recycled materials*5 for more than 25% of the plastics used in new models released worldwide by 2030 to help address the global waste plastic problem. To achieve this target, we are working to establish quality standards for recycled plastics and a raw material recovery scheme. In addition to our production target of achieving zero emissions at production plants*4 in Japan and overseas (zero landfill waste either directly or indirectly), we have newly set an annual 1% reduction target in our total waste versus BAU emissions*6 at business sites.

| Category | Target Year | Goal |

|---|---|---|

| Products | 2030 |

Pursue research and development targeting the use of recycled materials*1 for more than 25% of the plastic used in new models*2 by 2030

|

| Reduce total waste at business sites by 1% annually versus BAU emissions*4 | Zero emissions*5 at production plants in Japan and overseas*6 |

- *1

- Including material, chemical, and plastic recycling

- *2

- Excluding models supplied by OEMs

- *3

- Materials and suppliers with lower CO2 emissions and environmental pollution at the manufacturing stage

- *4

- Emissions under the current policy without further action (business-as-usual)

- *5

- Final disposal amount (total amount of direct landfill waste + landfill waste after intermediate processing) less than 0.5% of the total amount of waste (total amount of valuable resources + industrial waste + specially controlled industrial waste + general business-related waste)

- *6

- SUBARU: Gunma Plant, Tokyo Office, Utsunomiya Plant; Group companies in Japan: Fuji Machinery Co., Ltd., Kiryu Kogyo Co., Ltd., Ichitan Co., Ltd., Subaru Logistics Co., Ltd., Yusoki Kogyo K.K.; and Group companies overseas: Subaru of Indiana Automotive, Inc.

Initiatives

SUBARU promotes vehicle manufacturing with recycling in mind to make effective use of limited resources, working on resource efficiency throughout the entire lifecycle of automobiles, from raw material procurement and manufacturing to disposal.

In addition to continuing to promote the use of recycled materials and push for zero landfill at production sites both in Japan and overseas, we are also advancing research on the use of diverse sustainable new materials and developing upcycled products using scrap materials.

Product Initiatives

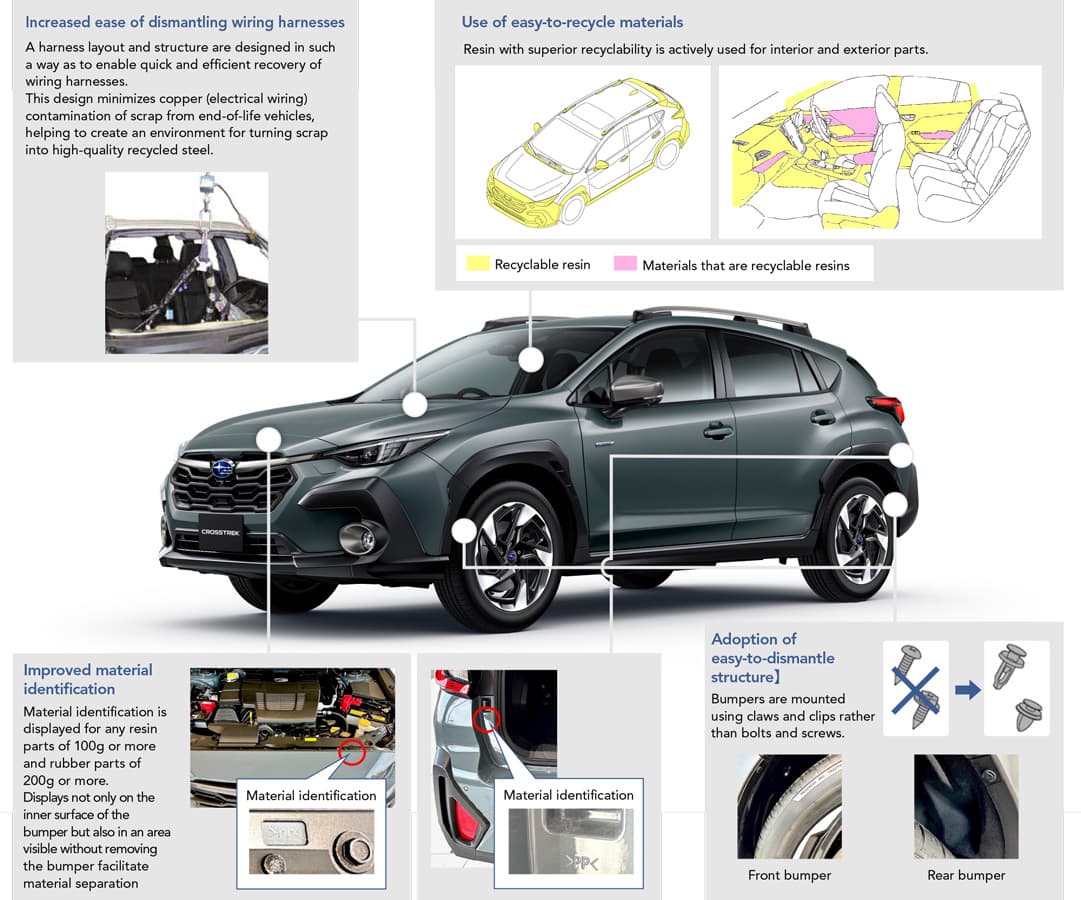

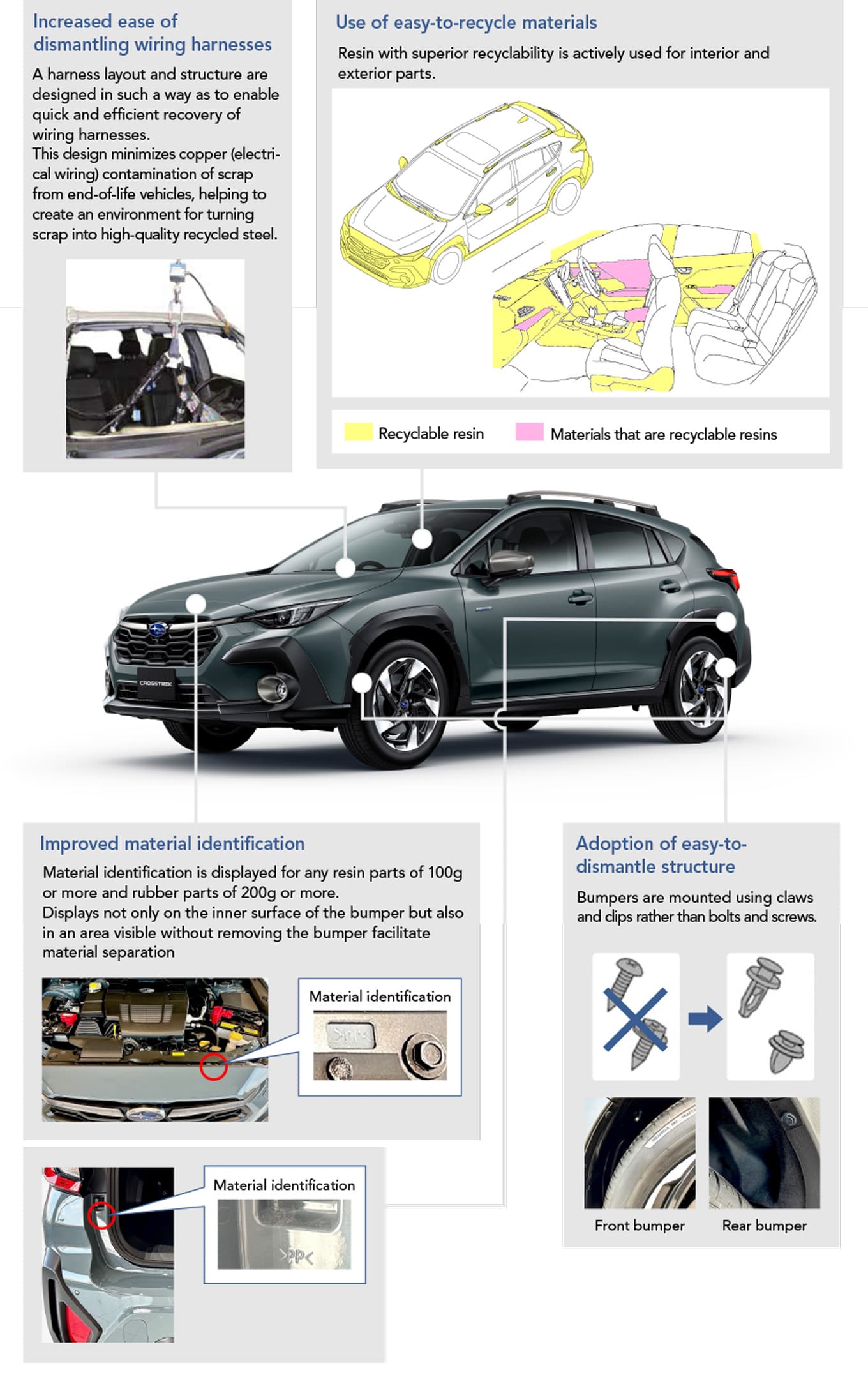

Design for Recycling

SUBARU incorporates recyclability into its automobile design process to make effective use of limited resources. In addition to providing a structure for easy disassembly and separation using an easy-to-disassemble wiring harness layout and visibility-oriented material identification, we use easy-to-recycle materials for parts in the interest of recycling.

Effective Use of Resources

Use of Recycled Materials

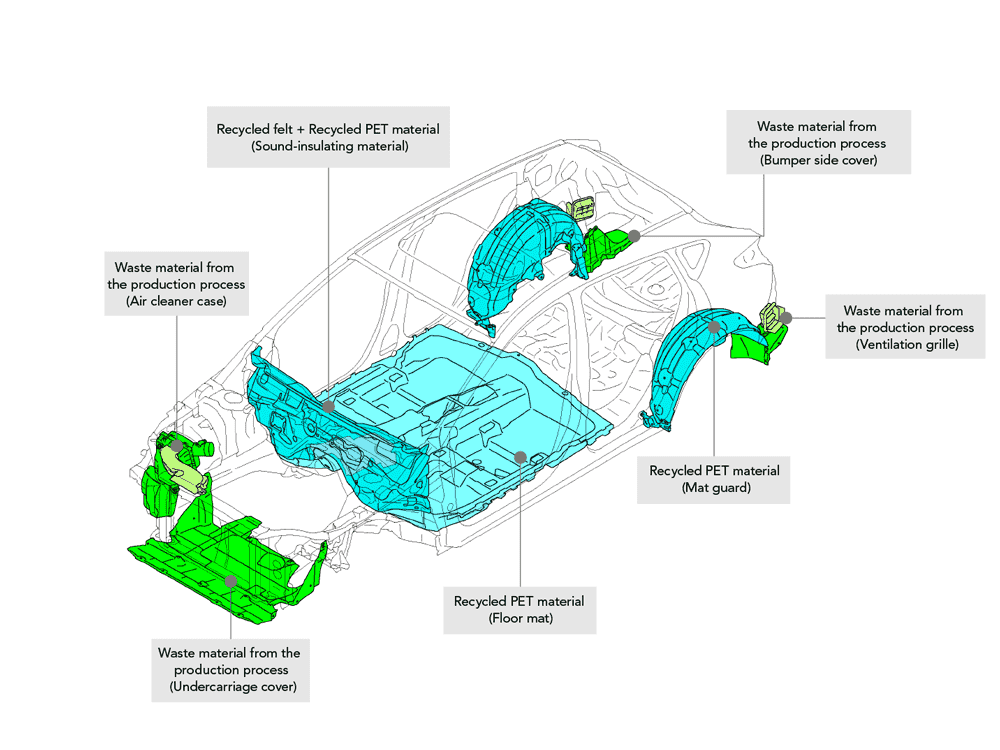

To contribute to realizing a resource-recycling society and a decarbonized society, SUBARU is proactively using recycled materials for resin parts and sound-insulating materials currently used in automobiles.

Example: 2025 Forester

Utilization of Biomass

Research on Plant-derived Materials such as Food Processing Residue

Mixing post-juicing fruit residues and thinned wood into resins allows us to cut down on petroleum-based resin use. This waste until now had to be incinerated in food processing and other areas, making it a social issue. By effectively utilizing this waste as raw materials for automobile parts, we are not only recycling resources but also advancing research into plant-derived materials so that people can resonate with the significance of using these materials and their natural feel.

(Prototype)

(Prototype)

Utilizing Other Recycled Materials

Utilization of recycled materials in floor mats (Subaru of America, Inc.)

Subaru of America, Inc. has developed environmentally friendly accessories, specifically floor mats made from materials recycled from marine debris. Both the surface and backing consist of 100% eco-friendly materials. Through the sale of these floor mats, we were able to use approximately 440 tons of recycled materials in 2024.

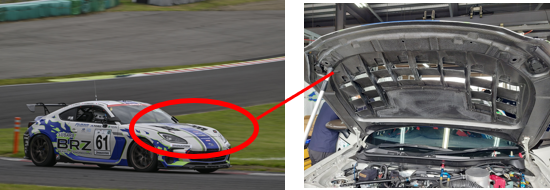

Research on High-performance Recycled Materials

In collaboration with SUBARU’s Team SDA* Engineering, the team leading our entry in the Super Taikyu Series of races, the SUBARU HighPerformanceX Future Concept, our vehicle for the competition, utilizes a carbon fiber rear wing, roof, door, and other items made of recycled carbon fiber from composite waste generated in aircraft parts manufacturing. This has reduced not only the vehicle’s weight but also its environmental impact.

The Super Taikyu Series is also carrying out an all-Japan co-challenge, transcending the boundaries between manufacturers to use motorsports as a platform to contribute to a sustainable society. As part of this co-challenge, recycled carbon fiber is also used for the hood of the MAZDA SPIRIT RACING MAZDA3 Bio concept, Mazda’s entry vehicle in the Super Taikyu Series.

In addition, the development of materials using recycled carbon fibers that approach the material properties of original carbon fibers as closely as possible and the construction of optimal design methods using recycled carbon fiber composite materials are being carried out in collaboration with other institutions. The research on the technology of continuous production of recycled carbon fiber and its application to aircraft has been adopted as a research program of the New Energy and Industrial Technology Development Organization (NEDO), a national research and development corporation. In this program, we are working to apply this technology to aircraft parts, while identifying technical issues and developing technology through industry-academia collaboration.

- *

- Acronym for SUBARU Driving Academy, a human resources development initiative to raise driving and evaluation skills of SUBARU engineers

Upcycling Initiatives to Recycle Production Scrap Materials into New Goods

In the concept of upcycling, items that were once disposed of are transformed into products of attractive value. SUBARU is focusing on scrap materials generated in the manufacturing process to create new value beyond the boundaries of automobiles, through its own initiatives as well as collaboration with peer companies.

Coin case made from cowhide scraps

SUBARU is helping to bring about a sustainable society by creating new value through upcycling activities, focusing on cowhide, normally used for steering wheels and interior trim, specifically parts of cowhide that are difficult to commercialize.

In 2024, we collaborated with FUJISUBARU Co., Ltd. and local universities, holding multiple workshops on making coin cases using cowhide scraps. We will continue these upcycling activities to enhance the effective use of resources and raise environmental awareness.

Aprons made from leftover cloth and cotton waste from factories (Takihyo Co., Ltd.)

SUBARU aims to enrich lifestyles and conserve the global environment through its goods. A direct outcome of connecting this idea to product development is our partnership with Takihyo Co., Ltd. to collect leftover cloth and cotton waste from factories and use the re-spun fabric to make aprons. These are designed with ample thought given to pocket location, combining design and environmental performance.

Eco-Friendly Shopping Bags Made from Leftover Fabric (TOYODA GOSEI Co., Ltd.)

SUBARU has created an eco-friendly bag (product name: Marche Bag) that is essential for everyday life by making use of scrap materials that would have been discarded during the production process of airbag fabric. As part of SUBARU’s commitment to safety, Marche Bag uses a patented reflective material that glows in the dark, enhancing safety on roads at night. Furthermore, we have used ergonomic theory to adjust the thickness of the handle so that even when carrying heavy loads, the weight does not put a strain on the arms. Furthermore, we have used ergonomic theory to adjust the thickness of the handle to eliminate strain on the arms.

Key Straps Made from Upcycled Fishing Net Waste (CANVAS CO., LTD.’s PoLER brand)

SUBARU collaborated with CANVAS CO., LTD. to address marine pollution by producing key straps made from discarded fishing nets. Portions of the straps are made from recycled fishing nets processed into a material called reamide. By using this reamide derived from used fishing nets, SUBARU contributes to resolving the marine debris problem while also reducing CO2 emissions compared to the use of virgin materials.

Site Initiatives

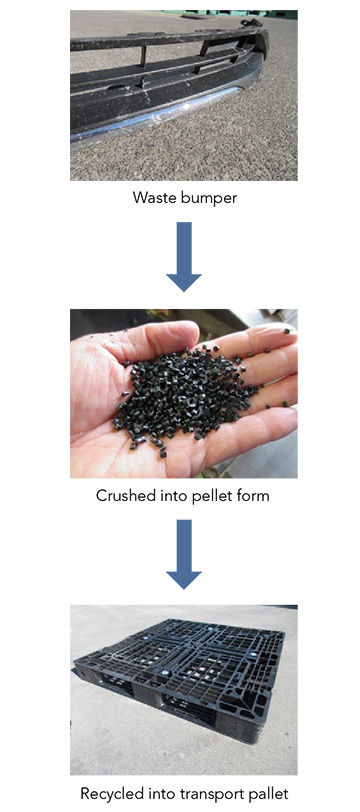

We have improved the accuracy of data through the introduction of an environmental performance aggregation system to ascertain the actual amount of valuable resources at Group companies in Japan. As waste is also an important resource, we have maintained zero emissions since FYE March 2015 through appropriate waste disposal, including recovery, reuse, and recycling. As part of its measures to deal with waste plastic, SUBARU has begun exploring waste plastic material recycling, including the reuse in automotive parts and other applications of reject bumpers from the manufacturing process.

Primary waste products and their recycled products

| Primary Waste Product | Primary Recycled Product |

|---|---|

| Wastewater treatment plant sludge | Raw material for cement |

| Paint sludge | Iron-making reducer |

| Waste plastics (solid fuels, etc.) | Refuse paper and plastic fuel (RPF) |

| Paper waste | Recycled paper, RPF, etc. |

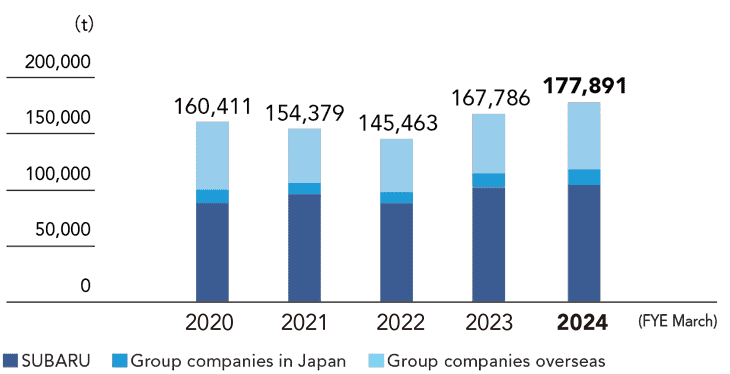

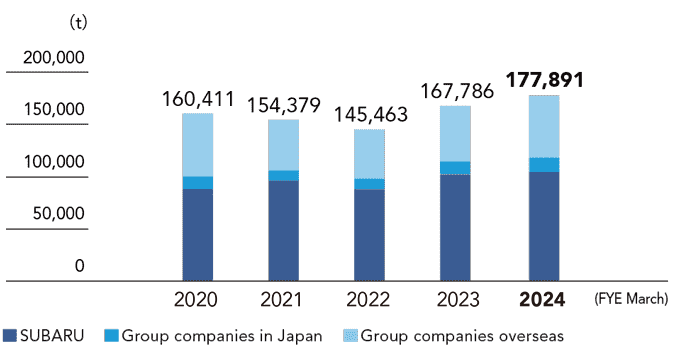

Waste Generation

Scope

SUBARU:

Gunma Plant, Tokyo Office, Utsunomiya Plant, Handa Plant, Handa West Plant, Ebisu Subaru Building, Accessory Center, SUBARU Training Center

Group companies in Japan:

Yusoki Kogyo K.K., Fuji Machinery Co., Ltd., Ichitan Co., Ltd., Kiryu Kogyo Co., Ltd., Subaru Logistics Co., Ltd., Subaru Kohsan Co., Ltd., Subaru Finance Co., Ltd., HBC Co., Ltd., FUJI AVIATION MAINTENANCE CO., LTD., SUBARU AUTO ACCESSORIES LTD.

Overseas Group companies:

Subaru of Indiana Automotive, Inc., Subaru of America, Inc., Subaru Canada, Inc., North American Subaru, Inc.

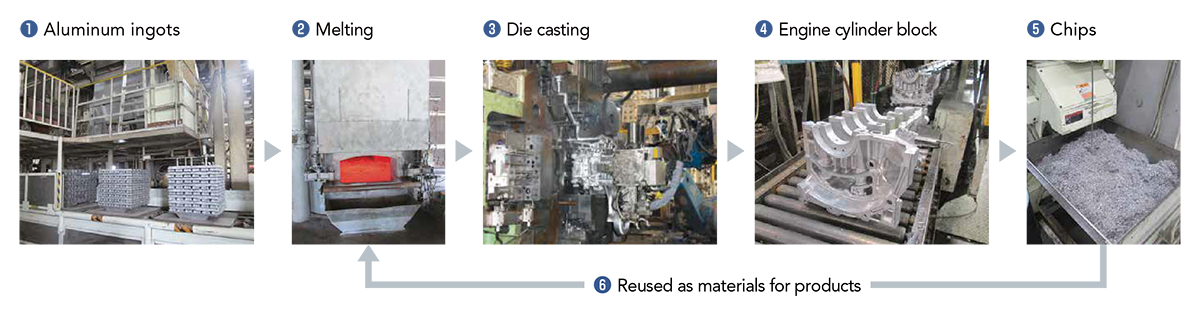

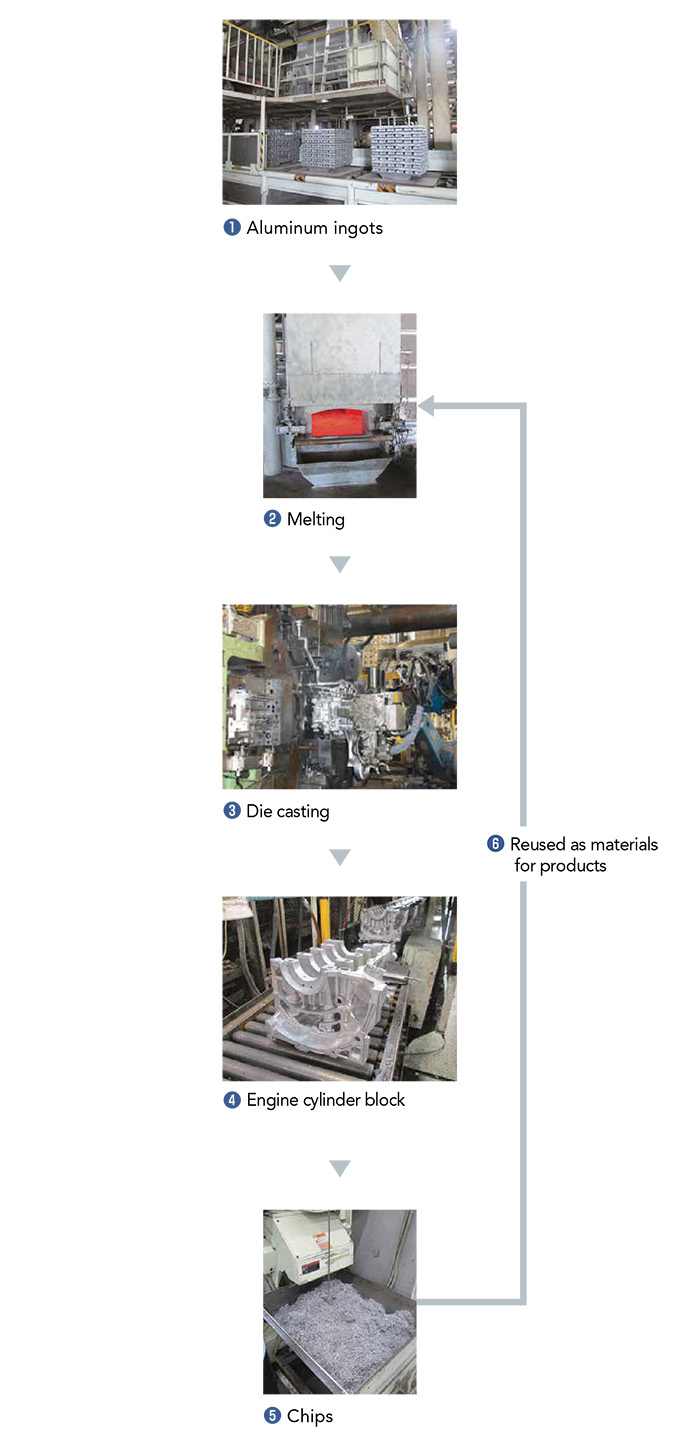

Recycling of aluminum chips

Employee Participation in Recycling Waste (Subaru of Indiana Automotive, Inc.)

Every year, Subaru of Indiana Automotive, Inc.’s employees bring in waste from their homes for proper recycling and disposal. In 2024, we recycled approximately 14 tons of hazardous waste, from oil and paint to electronic equipment and pharmaceuticals.

Initiatives at the Headquarters Building (Subaru of America, Inc.)

The SOA headquarters building has acquired silver LEED certification, and the company is making efforts to use recycled materials, such as using recycled wood for the lobby and café wall decorations and using recycled materials for some of the employee workstations and carpets. Many recycled materials are used in the construction of the entire building, from the steel frame and metal parts to the precast panels and finishes.

Eco Friendly Retailers (Subaru of America, Inc.)

SOA has launched the Eco-Friendly Program in collaboration with its retailers across the U.S. to promote the reduction of environmental impacts related to energy, water, and waste. To obtain certification under the program, retailers must meet standards in areas such as energy efficiency and recycling. As of 2024, 255 retailers, representing 40% of the program, have participated. In 2024, as part of the resource circulation initiatives under the program, approximately 3,750 tons of waste generated by the dealerships were processed for recycling.

Sustainable Subaru Gear (Subaru of America, Inc.)

Subaru of America, Inc. works with Staples Corporate to utilize 100% recycled plastic bags and recyclable shipping boxes at the time of sale. In 2024, more environmentally friendly products were added, accounting for approximately 42% of the total products offered.

In addition, Staples Corporate continued its partnership with EcoVadis, a sustainability rating agency, and maintained its Silver status, ranking in the top 25% of companies and industries evaluated. Staples Corporate also launched a responsible procurement in 2023, which is driving continuous improvement in the supply chain.

Food Waste Reduction Activities (Subaru of America, Inc.)

SOA has partnered with hospitality partner Eurest to strategically place scrap containers throughout the office to collect employees’ food waste. In FYE March 2025, approximately 4.3 tons of food waste was repurposed as animal feed and compost.

E-waste (Subaru of America, Inc.)

One of Subaru of America, Inc.’s initiatives is to appropriately recycle e-waste (waste from electric and electronic devices) from employee homes. In its 2024 Earth Day event, approximately 6 tons of e-waste was collected and processed for recycling.

Achieving a High Recycling Rate and Practicing Environmental Conservation (North American Subaru, Inc.)

North American Subaru, Inc. is actively promoting recycling activities through collaboration with local companies to help protect the environment and build a sustainable society. We partner with Green Beings in Detroit for the recycling of glass, plastic, and light metals, and with Advanced Computer Recycling for the recycling of electronic devices, thereby supporting the local economy and promoting resource recycling.

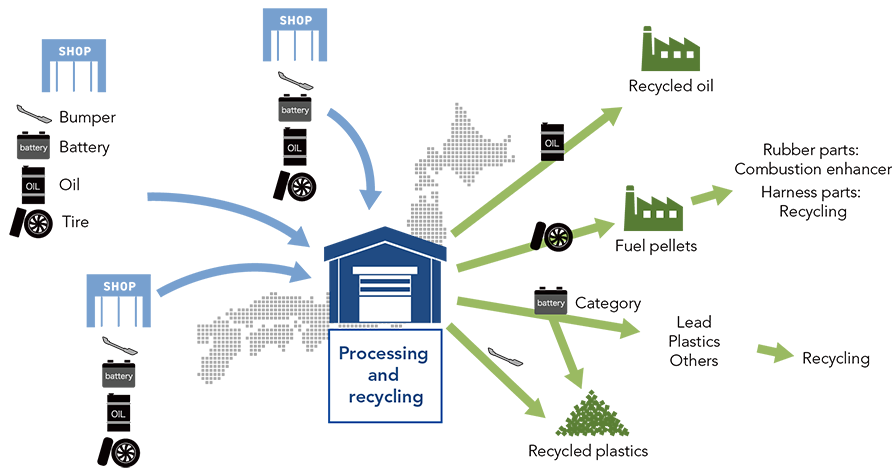

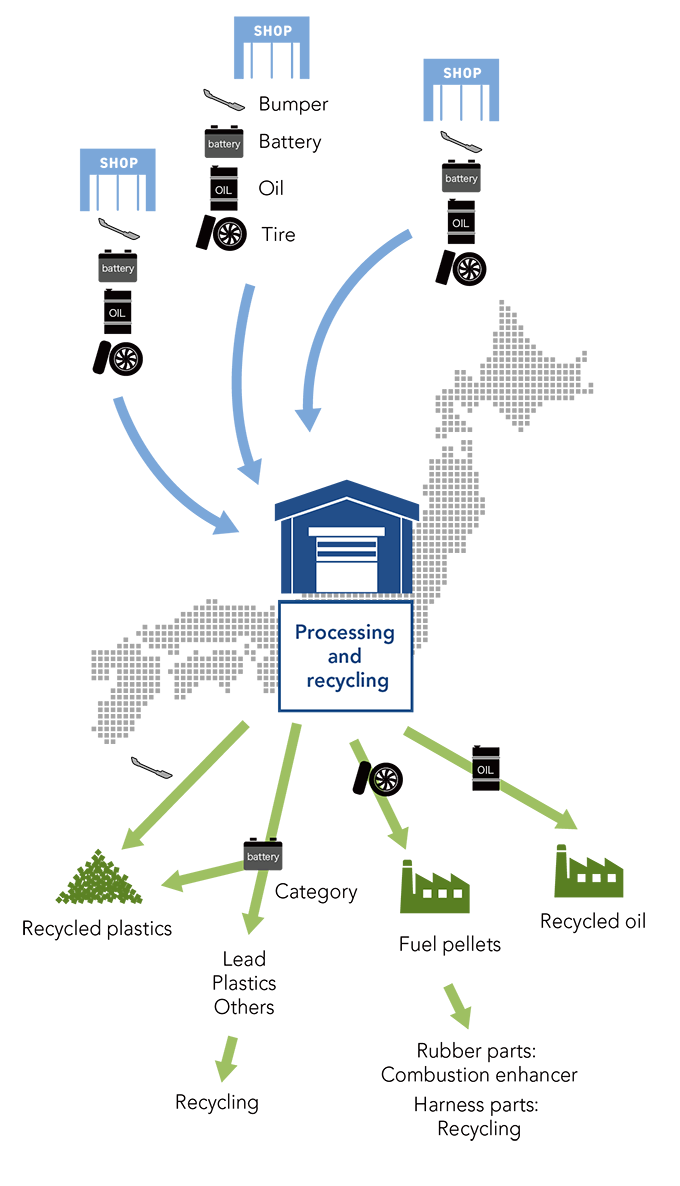

Sales Initiatives

Recycling and Achieving Zero Emissions

Zero Emissions of Waste from SUBARU Dealerships in Japan

Dealerships in Japan are committed to the proper management of waste generated from their business activities and to recycling to achieve zero emissions in Japan. In FYE March 2025, these initiatives resulted in the collection of 26,821 used bumpers, 156,172 lead batteries (containing 2,149 tons of lead material), 4,966 kL of oil, and 206,801 tires.

Zero emission initiatives led by dealerships, which work most closely with customers, are activities that will contribute more directly to environmental conservation in local communities. The initiatives are expected to help promote proper processing, recycling, and the effective use of resources.

Recycling of used bumpers

Recycling of Waste Oil

Waste oil generated at SUBARU dealerships in Japan during oil changes is converted to recycled fuel oil to replace conventional fuel oil through SUBARU’s zero waste emissions scheme. As an example, flower farmers in Yamagata Prefecture grow beautiful poinsettia and cyclamen every year using this recycled fuel oil to heat their greenhouses.

Waste cooking oil discharged by the operator of the employee cafeteria at the Subaru Logistics Co., Ltd. headquarters is recycled under the Fry To Fly Project scheme, which aims to convert the oil into sustainable aviation fuel (SAF). In FYE March 2025, this oil was converted to biodiesel fuel, and from April 2025, it has been recycled into SAF.

Zero Landfill Waste Joint Initiative in U.S. National Parks (Subaru of America, Inc.)

SOA has leveraged its expertise in zero landfill waste at Subaru of Indiana Automotive, Inc. (SIA), collaborating with suppliers, the National Parks Conservation Association, the National Park Service, and others since 2015 to reduce waste from three national parks: Yosemite National Park (California), Denali National Park and Preserve (Alaska), and Grand Teton National Park (Wyoming). To date, over 10,000 tons of waste has been diverted from landfills to recycling and composting.

SOA received the Silver Halo Award and the Corporate Stewardship Award in 2020 in recognition of zero landfill initiatives in national parks. Furthermore, in 2024, we supported waste reduction in more than 60 national parks, contributing to sustainable environmental conservation activities.

Subaru Park Zero Landfill (Subaru of America, Inc.)

Subaru Park, a soccer stadium in Chester, Delaware County, Pennsylvania, supported by Subaru of America, Inc, has become the first Major League Soccer Stadium to achieve zero-landfill status since 2021. In 2024, approximately 260 tons of waste generated at Subaru Park was processed for recycling.

Zero landfill initiative at Subaru of Mississauga

In collaboration with the local business U-PAK DISPOSALS, we collect and recycle waste material through the Energy from Waste program. In FYE March 2025, approximately 170 tons of waste was collected and effectively utilized as resources through this program.

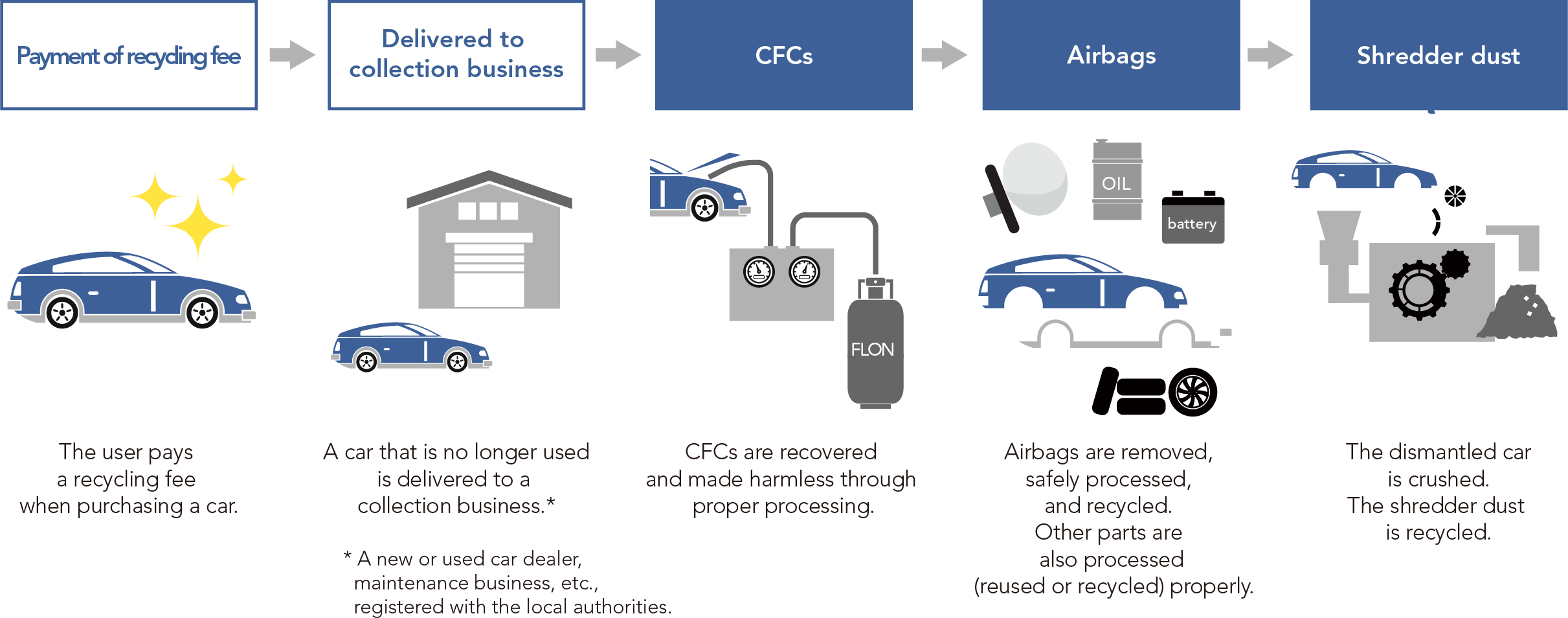

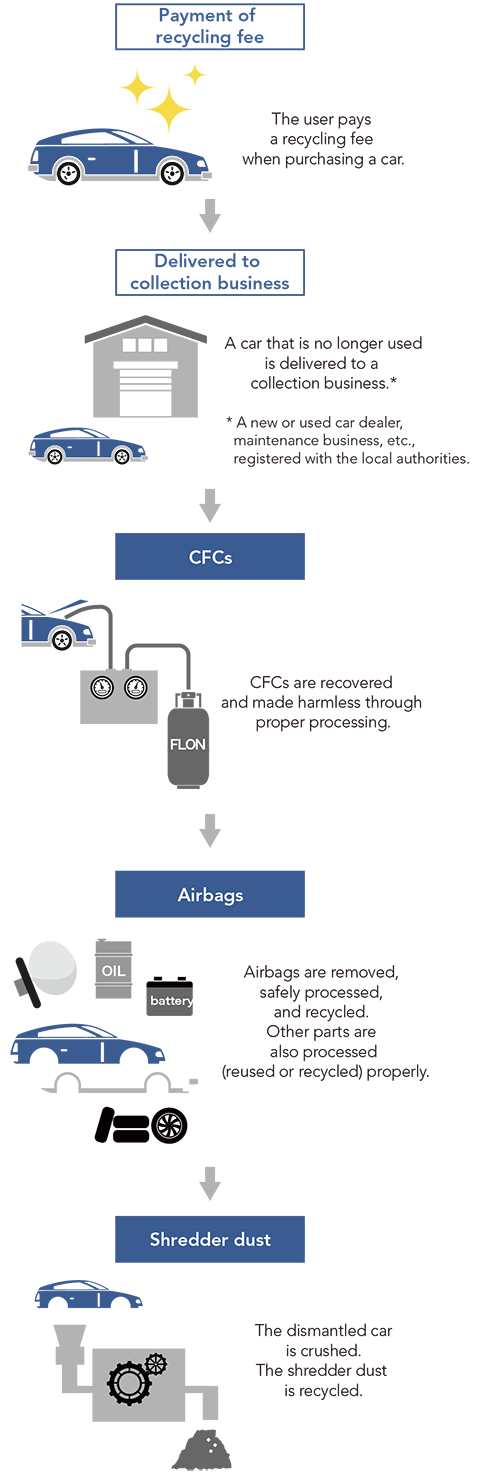

Proper Processing of End-of-life Vehicles

SUBARU is participating and collaborating actively in the building of an automotive recycling system to reduce the environmental impact of end-of-life vehicles. SUBARU is also focusing on promoting the development of easy-to-recycle vehicles, aimed at promoting the proper processing and raising the recycling rate of ASR, airbags, and CFCs.

In FYE March 2025, the ASR recycling rate was 96.8%, achieving the legal target of 70% for FYE March 2016 and thereafter. The airbag recycling rate was 96.5%, exceeding the legal target of 85%, and all CFCs recovered were processed properly.

Detailed information on the level of progress with these recycling initiatives and SUBARU’s other activities based on the Act on Recycling, etc. of End-of-Life Vehicles is disclosed separately on the web page indicated below.

- About the Act on Recycling, etc. of End-of-Life Vehicles (Japanese version only)

- Automobile shredder residue Recycling Promotion Team (ART) (Japanese version only)

Recycling Automobiles

Automobile Recycling Process

Act on Recycling, etc. of End-of-Life Vehicles

Under the Act on Recycling, etc. of End-of-Life Vehicles of Japan, car manufacturers are required to fully recover and properly recycle automotive shredder residue (ASR), airbags, and chlorofluorocarbons (CFCs) from their end-of-life vehicles.

SUBARU has been promoting the smooth, proper, and efficient recycling of ASR through the Automobile Shredder Residue Recycling Promotion Team (ART).* We also ensure proper processing of airbags and CFCs through operations of Japan Auto Recycling Partnership Ltd., established jointly with Japanese automakers and importers.

- *

- A team to promote the recycling of ASR, organized by 12 domestic automobile manufacturers and importers in 2003. The team plans the smooth, proper, and efficient recycling of ASR, a waste product that is classified as one of the Parts Specified for Recycling as defined by the Act on Recycling, etc. of End-of-Life Vehicles and required to be recycled under the law

Battery Recycling

Lithium-ion drive batteries that have been distributed in the Japanese market are being collected appropriately through a collection scheme by Japan Automobile Manufacturers Association, Inc. (JAMA). Nickel-hydride batteries installed in older vehicles are being properly collected and disposed of through SUBARU’s cross-regional certification scheme.

Use of Rebuilt Items

Use of Rebuilt Items (Subaru of America, Inc.)

Toward realizing a recycling-oriented society, Subaru of America, Inc. is promoting the use of rebuilt items to replace engines, transmissions, and other large parts to reduce environmental impact and ease the cost burden on customers. These rebuilt items* are reused after all replacement parts, such as seals and gaskets, have been removed and replaced with parts that meet the same high quality standards as genuine parts installed at the factory.

- *

- Repair parts such as engines, etc., for which consumable parts are replaced and usable parts are reused in accordance with inspection standards

Logistics Initiatives

Logistics

Reuse of Packaging Materials

Subaru Logistics Co., Ltd., which handles packaging and transport for complete knockdown (CKD) parts of SUBARU automobiles, has been actively working on reducing its environmental impact, focusing on the reuse of packaging materials. In FYE March 2025, the volume of reused materials handled exceeded 1,000 tons for the second consecutive year.

Going forward, we will continue to promote the reuse of materials to reduce environmental impact.

(FYE March)

| 2019 | 2020 | 2021 | 2022 | 2023 | 2024 | 2025 | |

|---|---|---|---|---|---|---|---|

| Amount reused (t) | 776 | 1,020 | 661 | 786 | 852 | 1,023 | 1,055 |

| Intensity (kg/vehicle) | 2.8 | 2.4 | 2.7 | 2.8 | 2.8 | 3.1 | 2.1 |

Reduction of Wrapping Materials on Bumpers for U.S. Market

At Subaru of America, Inc., non-colored bumpers imported from Japan are re-wrapped for protection during transport within the U.S. In FYE March 2021, we have launched an initiative to remove the need for re-wrapping in the U.S. by applying high-strength wrapping material with high shape stability before export from Japan.

Distribution Centers (Subaru of America, Inc.)

Subaru of America, Inc.’s regional distribution centers use returnable containers to reduce the amount of cardboard and wood used when transporting parts. In addition, we have introduced a nationwide e-waste recycling program to reduce final disposal of electronic waste. In 2024, we achieved an overall recycling rate of 90.8%.

Utilizing Environmentally Friendly Packaging Materials

The Company’s Parts Distribution Center has been working to utilize environmentally friendly packaging materials since FYE March 2022, including exploring a range of measures such switching from cardboard to paper packaging, use of packaging materials with 10% content of biomass plastic material, and switching from resin to cardboard pallets.

In addition, we are switching from wood to cardboard as a packaging material on shipment for large parts such as bumpers, engines, and transmissions. In addition, from FYE March 2024, we are working to eliminate excessive quality (e.g., eliminating, reducing size of, and adjusting thickness of materials) in order to eliminate plastic use.

Procurement Initiatives

SUBARU reuses remnant materials and scrap generated during production as well as end-of-life products that have been collected and other reusables as resources for materials, such as iron, aluminum, and plastics, which account for a large proportion of materials used. Through these efforts, we are promoting closed-loop recycling* to reduce natural resource consumption and waste generation.

- *

- A method by which waste and scrap generated during production along with end-of-life products are recycled as materials for parts of the same quality and then reused to make products of the same kind

| Raw Materials Used in Automobiles in FYE March 2025 | Recycling Method | |

|---|---|---|

| Iron | 620,126t | Delivered to dealerships in the form of iron scrap for reuse |

| Aluminum | 29,934t | Re-melted at plants and reused almost entirely |

| Plastics | 26,052t | Crushed again at plants and reused partially |