Quality: Aerospace Business

Our Approach

Quality is the foundation of “Enjoyment and Peace of Mind,” SUBARU’s core value. With “quality first” as our slogan, we are working to provide high-quality products and services.

Quality Policy

At SUBARU, quality is our highest priority as we earn the trust of our customers.

- We will deliver long-lasting products that our customers can use with peace of mind.

- We will continually improve our products and services by always listening closely to our customers’ voice.

- We will be a good corporate citizen in all markets where we do business by ensuring compliance with all internal rules, local laws, regulations and social norms.

Management System

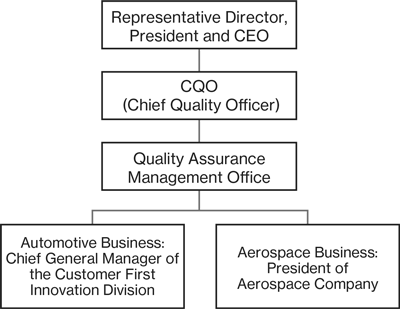

At the SUBARU Group, quality assurance activities, including for all affiliated companies in Japan and overseas, are overseen by the CQO (Chief Quality Officer), with the President bearing ultimate responsibility. In addition, we have established a Quality Assurance Management Office to oversee and manage quality assurance. Under the purview of the CQO, the Chief General Manager of the Customer First Innovation Division oversees quality assurance activities for the Automotive Business, while the president of the Aerospace Company oversees quality assurance activities for the Aerospace Business.

We have established a system that enables us to respond quickly and consistently to quality issues across the entire Group, thereby increasing the speed and effectiveness of global quality improvement.

Aerospace Business

At SUBARU’s Aerospace Company, we maintain and promote the quality management system (QMS) based on our Quality Policy and JIS Q 9100 standards, and work on improving the system to enhance quality.

Under the direction of the Group’s CQO, the president of the Aerospace Company has overall responsibility for establishing, implementing, and continuously improving the quality management system from a customer-focused perspective, and leads the entire Aerospace Company in this effort.

Management of Product Safety and Quality

The Aerospace Company has obtained certification for its quality management system. The effectiveness of the system is maintained through regular internal audits and renewal inspections by a third-party certification body.

- JIS Q 9100 Quality Management SystemsーRequirements for Aviation, Space and Defense Organizations

Scope of certification: All plants (Utsunomiya Main Plant, South Plant, South Second Plant, Handa Plant, Handa West Plant, Kisarazu Office, Head Office)

Additionally, we have been certified by the Ministry of Land, Infrastructure, Transport and Tourism as a facility meeting the technical standards for aircraft manufacturing, and we undergo renewal inspections at intervals specified by law.

- Certified workplaces based on Article 20 of the Civil Aeronautics Act

- (Certified capabilities)

- Capabilities to design aircraft and inspect the completed design, capabilities to manufacture aircraft and inspect the completed aircraft, capabilities to perform maintenance on aircraft and inspect the performed maintenance, capabilities to perform maintenance or alteration on aircraft, capabilities to manufacture components and inspect completed components, capabilities to perform repair or alteration on components

The following are currently undergoing audits for certification by the Acquisition, Technology & Logistics Agency.

- Ministry of Defense Directive No. 32, Directive on Ensuring Safety of Aircraft: Design organization approval under Article 25

Quality Meetings

The Aerospace Company holds Quality Meetings at least once a year to ensure that the quality management system achieves its intended results. Based on various analysis results regarding product and operational processes, such as internal audits conducted within the Aerospace Company, external assessments (customer satisfaction, audit findings, etc.), and audit results from third-party organizations, the company deliberates on changes to the Quality Management System (QMS), resource requirements, and strategies for addressing identified risks.

Quality is Our Promise to Customers

Ensuring flight safety is the top priority for the Aerospace Company. Risks with the potential to compromise flight safety include parts falling off, loss of control, and engine failure. These risks could lead to crashed planes and, in the worst cases, affect human life.

In order to minimize such risks, the Aerospace Company thoroughly checks product safety as early as the aircraft parts manufacturing stage, including rigorous inspection of inherent product quality and process quality on assembly lines, as well as flight tests on completed aircraft.

“Inherent product quality” refers to the functionality and safety that can be confirmed by inspecting finished aircraft parts and other items. “Process quality” refers to the standardization of manufacturing procedures (work, inspections), their implementation in accordance with those standards, and the recording of the results of manufacturing. We believe that satisfying both of these requirements is the way to fulfill the trust placed in us by our customers, as stated in our Quality Policy. We act on this with the understanding that it is our promise to our customers.

In order to fulfill our promise to our customers, the Aerospace Company is committed to improvement, one of the principles of the JIS Q 9100 standards regarding quality management system, and is also engaged in training the necessary human resources.

In addition, since aircraft manufacturing requires cooperation from many business partners, the Aerospace Company is engaged in quality control not only within the company but also with respect to its business partners.

Initiatives

Improvement Initiatives

The Aerospace Company carries out improvement activities tailored to the characteristics of its operations and processes to correct, prevent, or mitigate undesirable effects.

| Item | Description |

|---|---|

| Methods and activities for making improvements |

|

| Tools for making improvements | Electronic corrective action system (in operation since 2010; more than 5,000 corrections made) |

| Sharing of improvement activities | Improvement activity debriefing sessions: Held once a year for the Aerospace Company (employees with excellent activities participate in SUBARU-wide debriefing sessions) |

Providing Human Resource Training: Quality-Related Training

We conduct quality assurance-related training for all Aerospace Company employees or those involved in specific departmental tasks. We also provide training for product warranty inspectors.

| Course Topic | Target | Frequency | |

|---|---|---|---|

| Quality-related training | Quality refresher training | All employees | Twice a year |

| QMS consolidation training | All employees | Twice a year | |

| Compliance training | All employees | Twice a year | |

| Training on Quality Month events | All employees | Once a year | |

| Training on Compliance Month events | All employees | Once a year | |

| Human factor training | Mainly employees working at Civil Aeronautics Act-certified workplaces | Once a year | |

| Aeronautical safety training | Mainly employees working at Civil Aeronautics Act-certified workplaces | Once a year | |

| Education for employees in certified workplaces | Mainly employees working at Civil Aeronautics Act-certified workplaces | Once a year | |

| Training for inspectors | New accreditation/periodic renewal training | Inspectors | Upon accreditation / every 3 years |

| Basic manners training for inspectors Techno-school |

Inspectors | Once a year | |

| Skills enhancement training for inspectors | Inspectors | Once a month | |

| Skills training Techno-school |

Inspectors | Ten times a year | |

Initiatives for Ensuring Flight Safety

We have established a flight safety campaign period to raise employee awareness on the topic. In addition, we conduct aviation rescue drills to enable us to respond quickly in the event of an accident.

| Name | Description | Frequency |

|---|---|---|

| Flight safety campaign | Monthly events such as flight safety-related training and simultaneous site inspections | Twice a year |

| Aviation rescue drills | Drills to respond to aircraft accidents | Once a year |

In addition, as a safety requirement, we maintain a safety management system (SMS) required by the Ministry of Land, Infrastructure, Transport and Tourism based on standards set by the International Civil Aviation Organization (ICAO). The Aerospace Company applies the SMS to certified workplaces under Article 20 of the Civil Aeronautics Act. The company holds four internal meetings a year to review the status of activities in accordance with the SMS and confirm compliance with SMS requirements.

Quality Management for Business Partners

Manufacturing aircraft requires cooperation from many business partners. In addition to initial inspections at the time of contract signing, we conduct quality audits every four years (or every two years, depending on the business partner) for each business partner, and take prompt corrective measures if any problems are found. We are working to maintain and improve quality throughout the supply chain by providing training opportunities on quality improvement and following up on corrective guidance.

| Name | Description | Frequency |

|---|---|---|

| Quality audit | SUBARU quality requirements (standard requirements) based on AS/EN/JIS Q 9100 |

|

| Training | Seminars on quality improvement, etc | Three times a year |

| Corrective measures | Quality improvement activities when a downward trend in quality or other issue is confirmed | Ad-hoc |

| Corrective measures using the electronic corrective action system used by the Aerospace Company | Ad-hoc when correction is necessary |