Subaru Starts Test Operations of Manufacturing Equipment

Equipped with All-Solid-State Batteries

Tokyo, August 18, 2025 – Subaru Corporation began test operations in August using the ceramic-packaged all-solid-state battery “PSB401010H,” manufactured by Maxell, Ltd. (Headquarters: Minato-ku, Tokyo; “Maxell”), in industrial robots and programmable logic controllers*1 at the Oizumi Plant, Subaru’s engine and transmission production site in the Gunma Manufacturing Facility.

|

|

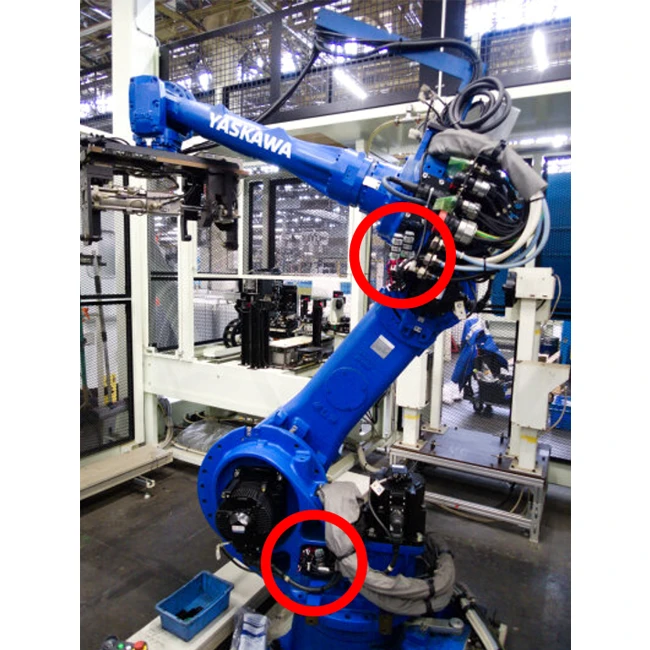

| Industrial Robot Equipped with All-Solid-State Batteries (Red circle indicates location of all-solid-state battery-equipped power module *²) |

Power Module Equipped with Maxell’s All-Solid-State Batteries |

In the automobile manufacturing process, industrial robots that enable factory automation*3 are typically equipped with primary batteries*4 as backup power supplies to protect memory. Normally, industrial equipment using primary batteries requires battery replacement every one to two years, and used batteries are disposed of as industrial waste. In this initiative, by installing all-solid-state batteries in the industrial robots used at our factory, Subaru aims to reduce both industrial waste and maintenance work for industrial robots by utilizing the long battery life of over 10 years without replacement. Through these efforts, Subaru aims to realize its goal of a circular economy.

To achieve the goal of “Delivering Happiness to All,” the Subaru Group is promoting sustainability on a Group-wide, global basis under its Subaru Global Sustainability Policy.

Subaru will continue to pursue sustainable growth as a truly global company, while helping to create a more enjoyable and sustainable society.

- Subaru Group Sustainability & CSR

https://www.subaru.co.jp/en/csr/